Applications and sample parts

Sample parts from our material portfolio

The material variety of Apium offers the highest component quality adjusted to your application.

Convince yourself and order a test print. Our service team will be happy to advise you on the appropriate choice of material.

Apium PEEK CFR

By adding of 30% carbon fibers, the thermal and mechanical properties of the already established material PEEK are additionally strengthened. The increased strength of the material will allow you to use Apium PEEK CFR in wider mechanical engineering applications. In addition, the material can be easily post-processed, so that an excellent surface quality can be achieved.

Transmission Gear

| Process time | Weight | Filament length | Material price |

| 6 h 17 | 43 g | 13.53 m | 26.66 € |

Field of application: mechanical engineering

Characteristics: Components made of Apium PEEK CFR exhibit a very high stiffness. In this example, the surface of the shaft was reworked, resulting in a high-quality end product.

Component for CNC-Machining

| Process time | Weight | Filament length | Material price |

| 7 h 13 | 32.54 g | 10.25 m | 20.17 € |

Field of application: Production equipment

Characteristic: This component was originally modeled as a CNC processing tool. It can be 3D-printed from Apium PEEK CFR without extensive redesign.

Thermo Forming Mould

| Process time | Weight | Filament length | Material price |

| 12 h 21 | 46.28 g | 15.3 m | 28.69 € |

Field of application: Production equipment

Characteristic: The cross-section of this thermo forming tool shows how component strength can be maintained while the material usage is reduced through a suitable in-fill structure.

Seal Connector

| Process time | Weight | Filament length | Material price |

| 18 h 40 | 101.37 g | 31.9 m | 62.85 € |

Field of application: Gases and liquids

Characteristic: PEEK CFR shows high mechanical strength and chemical non-reactivity. The design of the channel structures and guides can be freely configured.

Gear

| Process time | Weight | Filament length | Material price |

| 5 h 45 | 16.98 g | 5.1 m | 10.53 € |

Field of application: Gears, mechanical engineering

Characteristic: PEEK CFR can be post-processed very well. The component was sandblasted for surface finishing. This results in a fine and mat surface.

Shell Bearing (Split Bearing)

| Process time | Weight | Filament length | Material price |

| 8 h 08 | 43.11 g | 13.57 m | 26.73 € |

Field of application: bearings

Characteristic: The strength and sliding properties of additive printed PEEK CFR can be improved by post-processing, in this case sandblasting. The layer spacings otherwise known from material extrusion disappear and an even, high-quality surface remains.

Apium PEEK

PEEK (polyether etherketone) is a semi-crystalline thermoplastic that is ideally suited for applications in extreme thermal, chemical and mechanical environments. It allows users to reduce overall weight, extend service life and, thanks to the processability of the material extrusion process, offers greater design freedom.

Three Channel Swirl Mixer

| Process time | Weight | Filament length | Material price |

| 7 h | 26.9 g | 8.46 m | 15.06 € |

Field of application: chemicals, aggressive media

Characteristic: PEEK is chemically non-reactive and therefore suitable as an material for most chemically aggressive media. Thanks to the additive manufacturing process, internal channel structures can be easily designed, which for example help to improve liquid mixing.

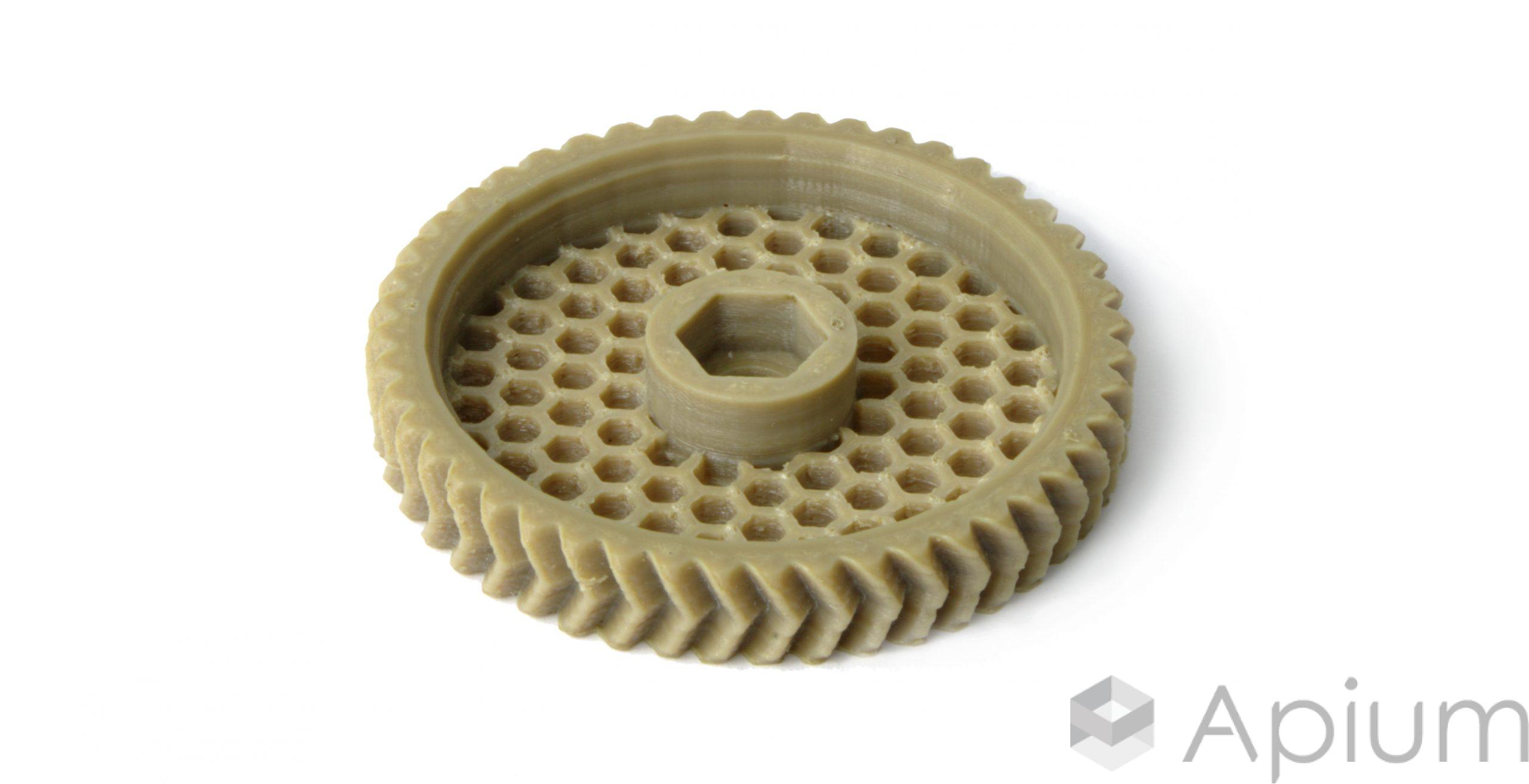

Gear Wheel with Arrow Gearing

| Process time | Weight | Filament length | Material price |

| 1 h 47 | 11.0 g | 3.42 m | 6.82 € |

Field of application: mechanical engineering

Characteristic: Weight reduction through honeycomb structure: The arrow gearing allows the transmission of large torques without generating axial forces. The bearing wear is correspondingly low. The production of such gearings is very complex and expensive in conventional manufacturing.

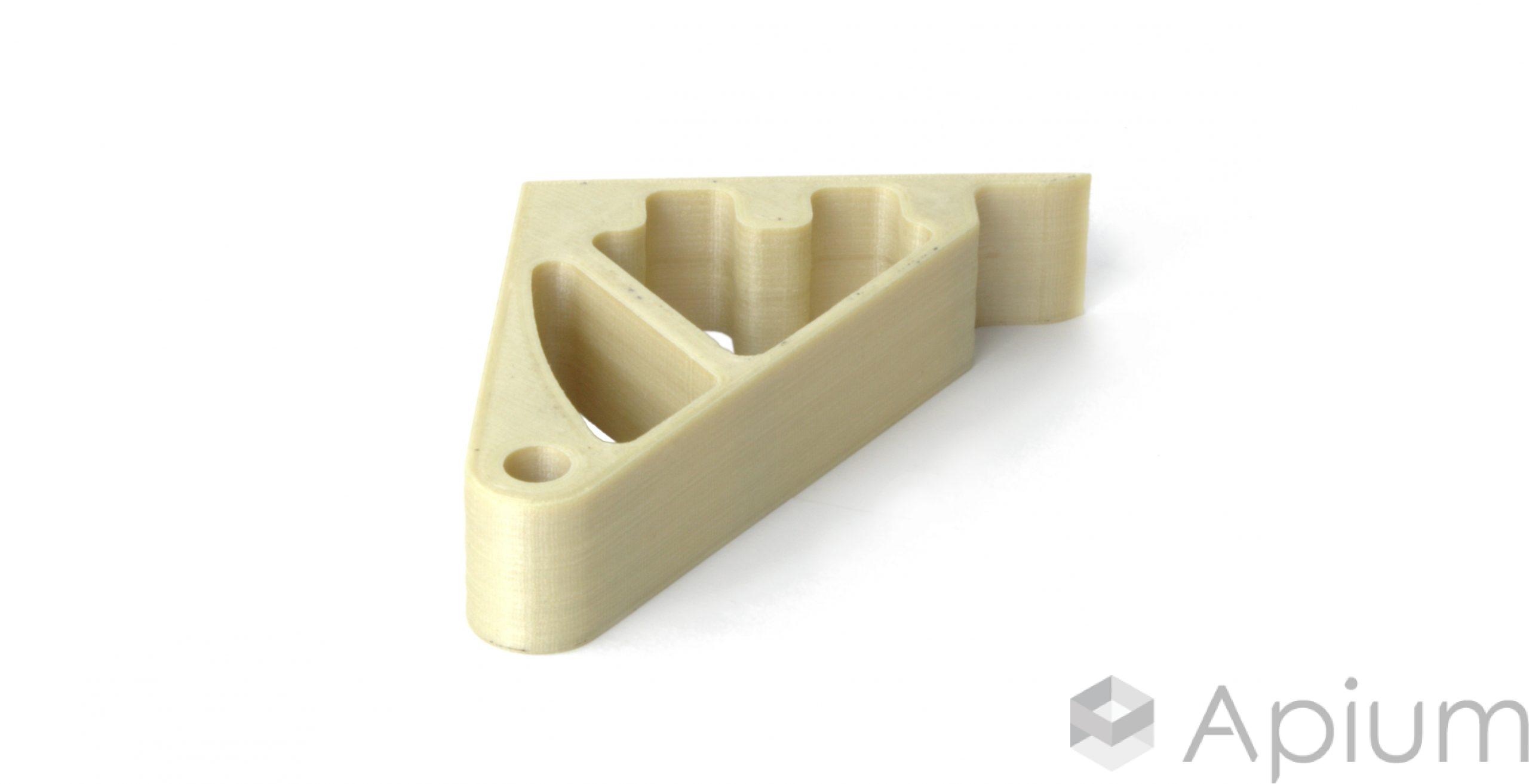

Lightweight Angle

| Process time | Weight | Filament length | Material price |

| 2 h 58 | 14.1 g | 4.44 m | 7.84 € |

Field of application: mechanical engineering

Characteristic: Additive manufacturing allows the production of lightweight components with little material input, which however can absorb high forces. Coupled with the appropriate mechanical polymer properties, PEEK is an ideal material for mechanical engineering applications.

Multi-Channel Swirl Mixer

| Process time | Weigth | Filament length | Material price |

| 19 h 12 | 101 g | 31.77 m | 56.56 € |

Field of application: chemistry, liquids, heat transformers

Characteristic: The creation of complex channel structures is easy for additive manufacturing. These can be used for mixing purposes or heat exchange. Here the temperature stability of such a procedure must be considered. PEEK as a high-temperature resistant material is ideally suited for this purpose.

Nets

| Process time | Weigth | Filament length | Material price |

| 3 h 47 | 3.2 g | 1.0 m | 1.19 € |

Field of application: Filtration

Characteristics: PEEK as a chemically resistant material is perfectly suited for use in filtration.There are almost no limits to the design freedom of the meshes.

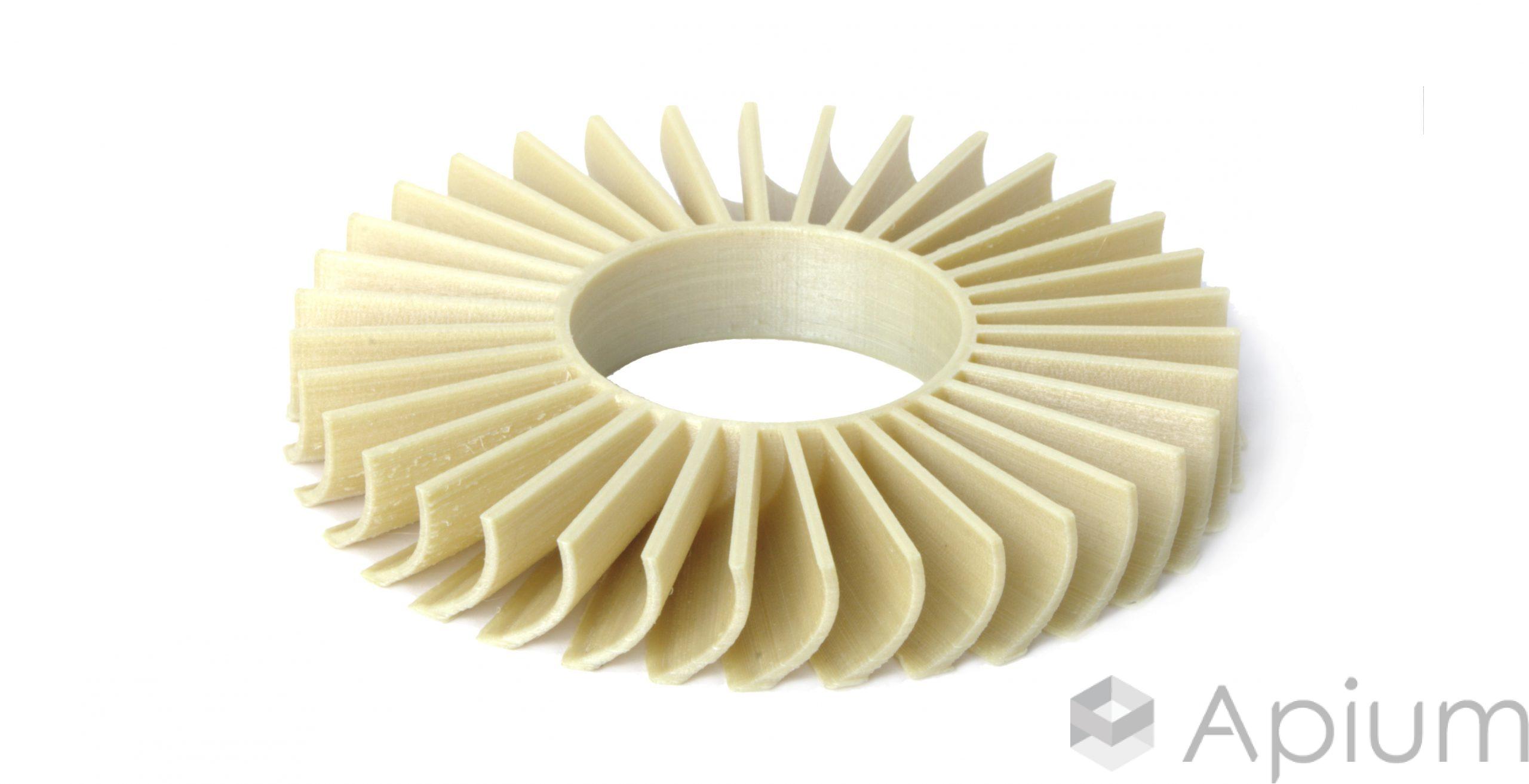

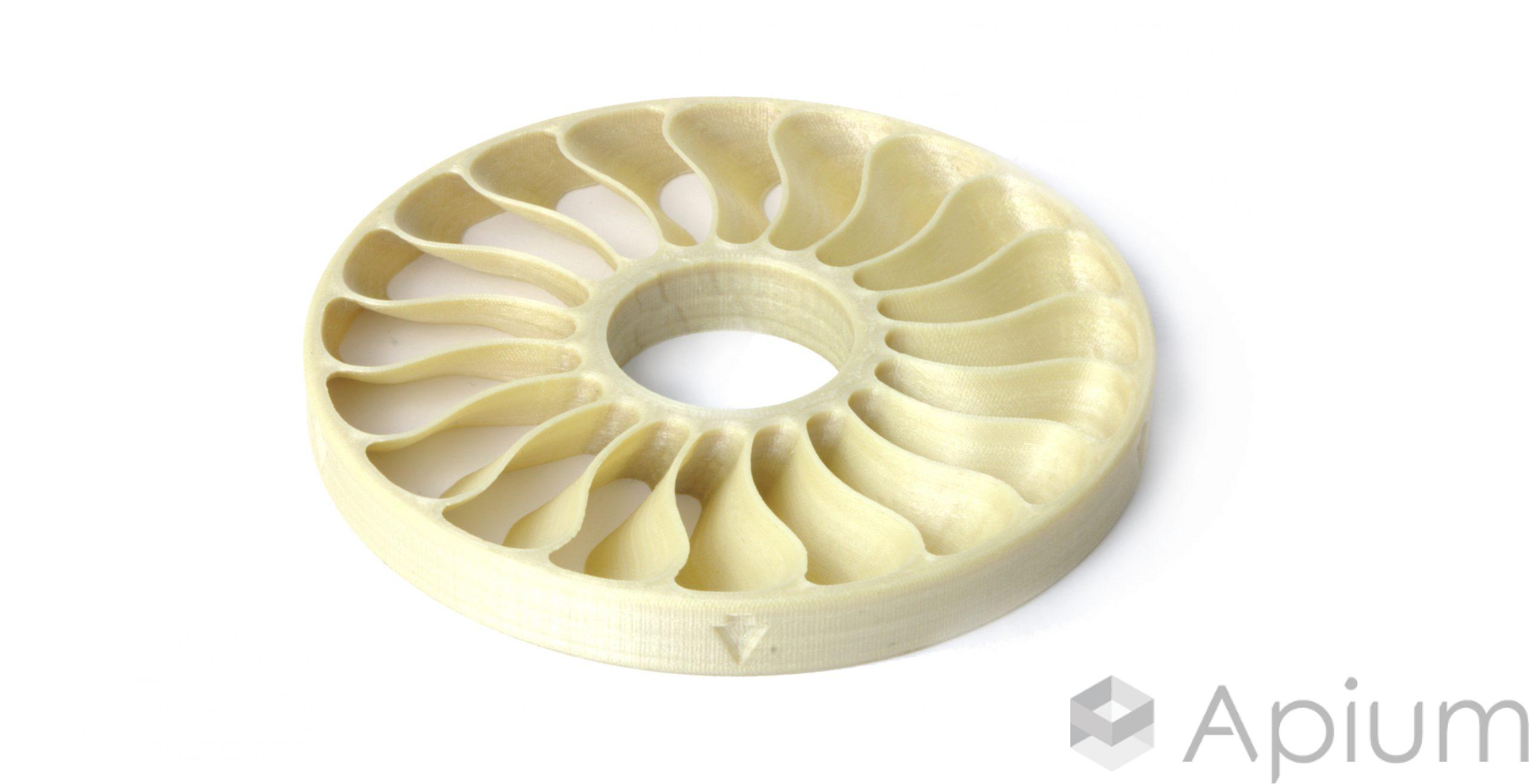

Impeller

| Process time | Weight | Filament length | Material price |

| 3 h 23 | 12.3 g | 3.86 m | 6.89 € |

Application: Pumps, high vacuum

Characteristics: PEEK is not only used for chemical and radiation-intensive environments, but is also often used in high vacuum technology. The printed materials do not emit gases and can be used in a variety of applications.

Apium PEEK GFR

PEEK GFR (glass fiber reinforced) is a compound that combines the excellent chemical and thermal properties of PEEK with the high stiffness of glass. This combination enables components with high dimensional stability maintaining the natural PEEK colored aesthetics.

Connector

| Process time | Weight | Filament length | Material price |

| 1 h 51 | 8.1 g | 2.33 m | 5.51 € |

Field of application: Chemistry, liquids

Characteristic: Glass fiber reinforced PEEK is characterized by its high strength and chemical resistance. Thanks to the glass fiber, electrical and thermal resistances are also increased.

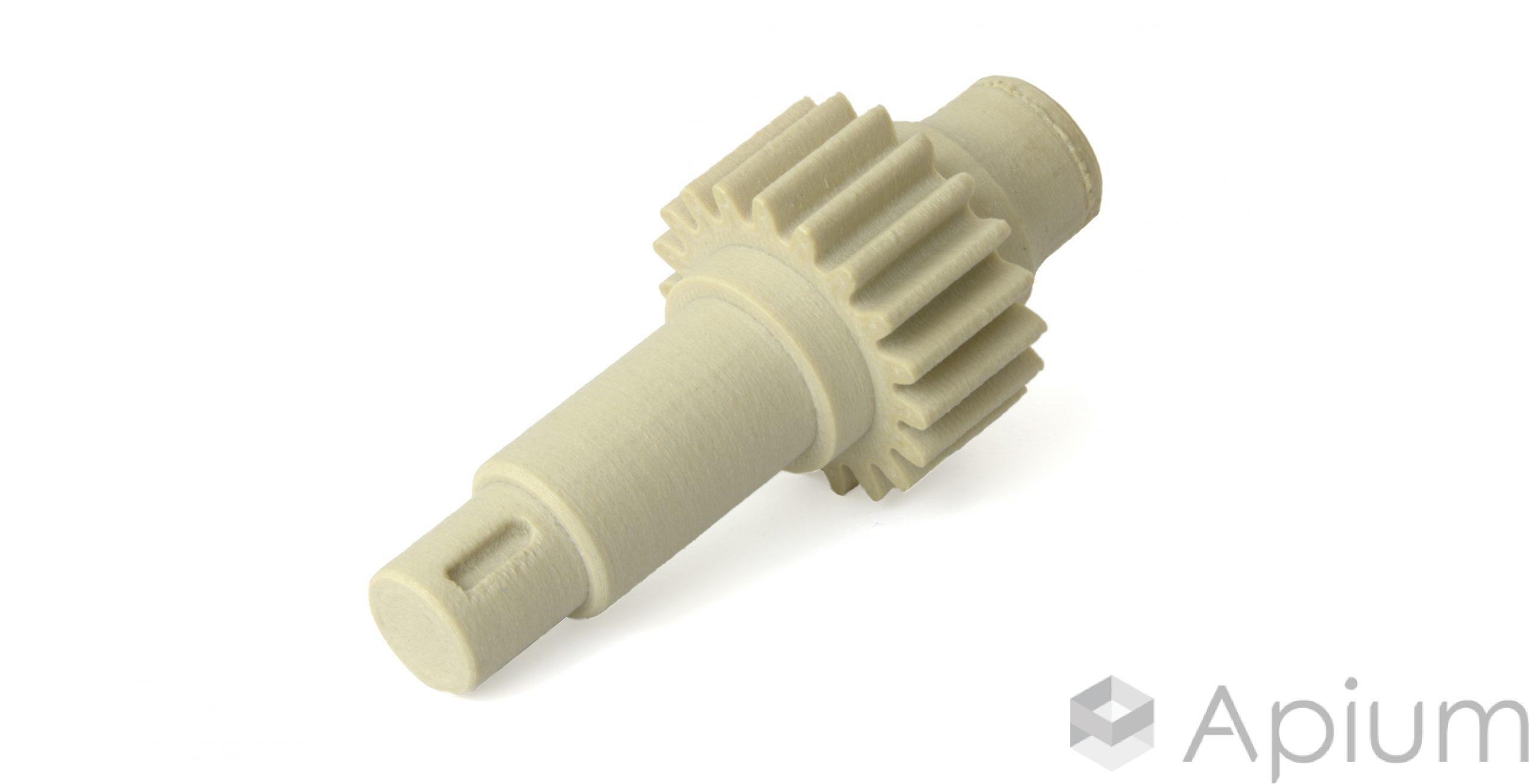

Transmission Gear

| Process time | Weight | Filament length | Material price |

| 3 h 55 | 40.9 g | 11.81 m | 8.03 € |

Field of application: Mechanical engineering, gears

Characteristic: The thermal strength of PEEK GFR combined with the high mechanical load capacity and high dimensional stability make it a popular material in mechanical engineering.

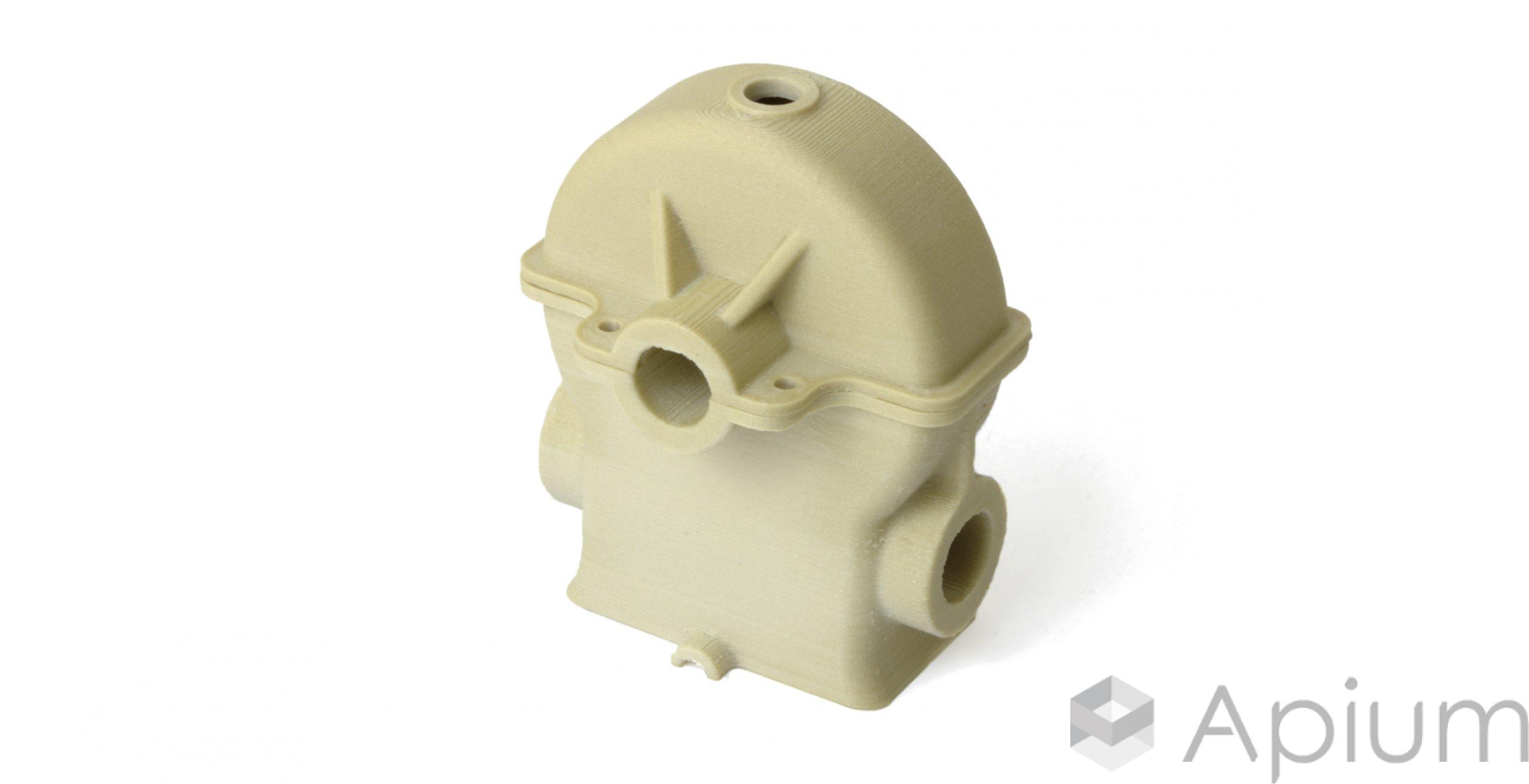

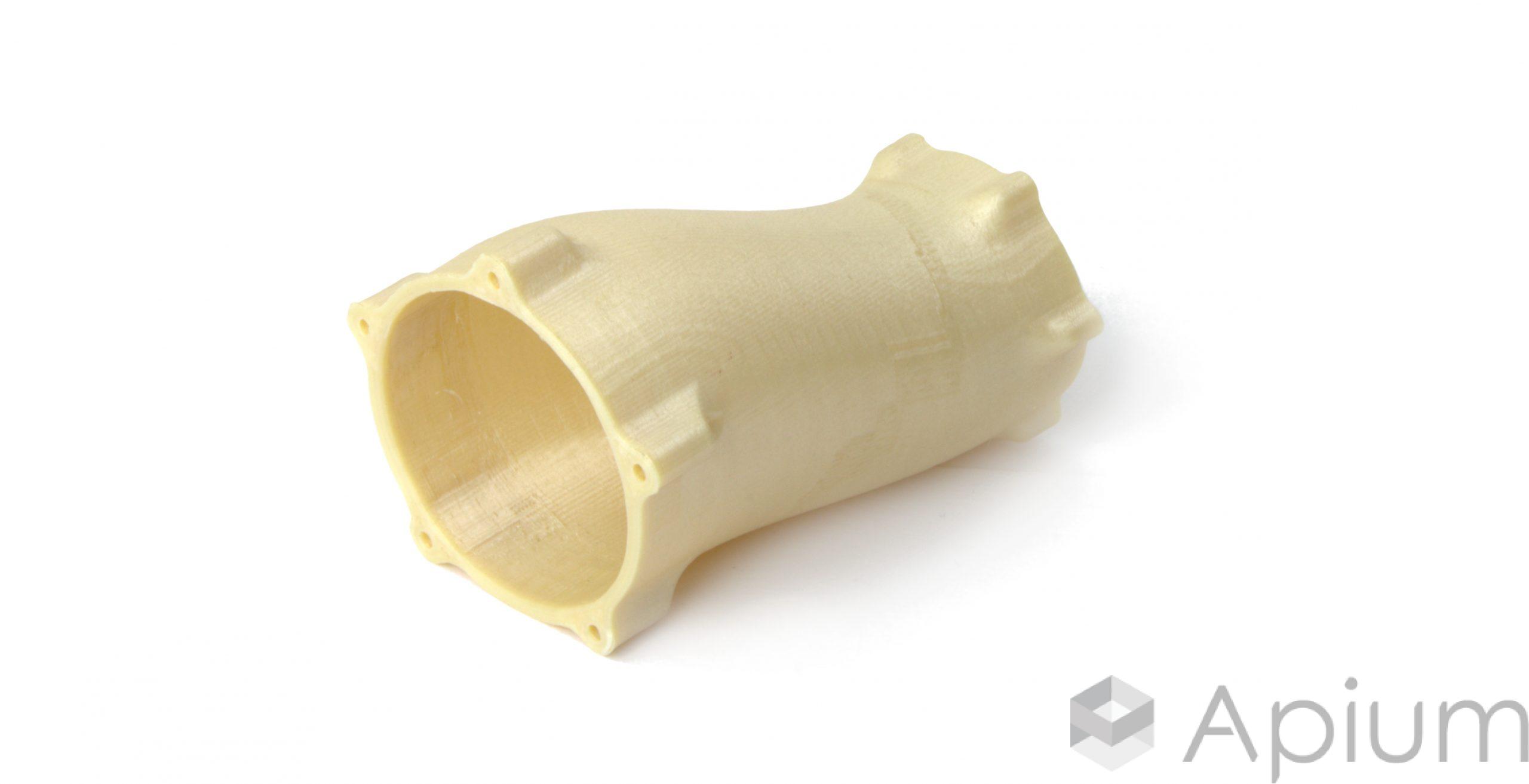

Gearbox Housing

| Process time | Weight | Filament length | Material price |

| 17 h 44 | 116.7 g | 33.69 m | 79.36 € |

Field of application: Mechanical engineering

Characteristic: PEEK is ideally suited as a housing material for a variety of chemically, physically, thermally or biologically demanding environments. The resistance of PEEK GFR as well as the high dimensional stability provide the necessary properties to withstand these conditions.

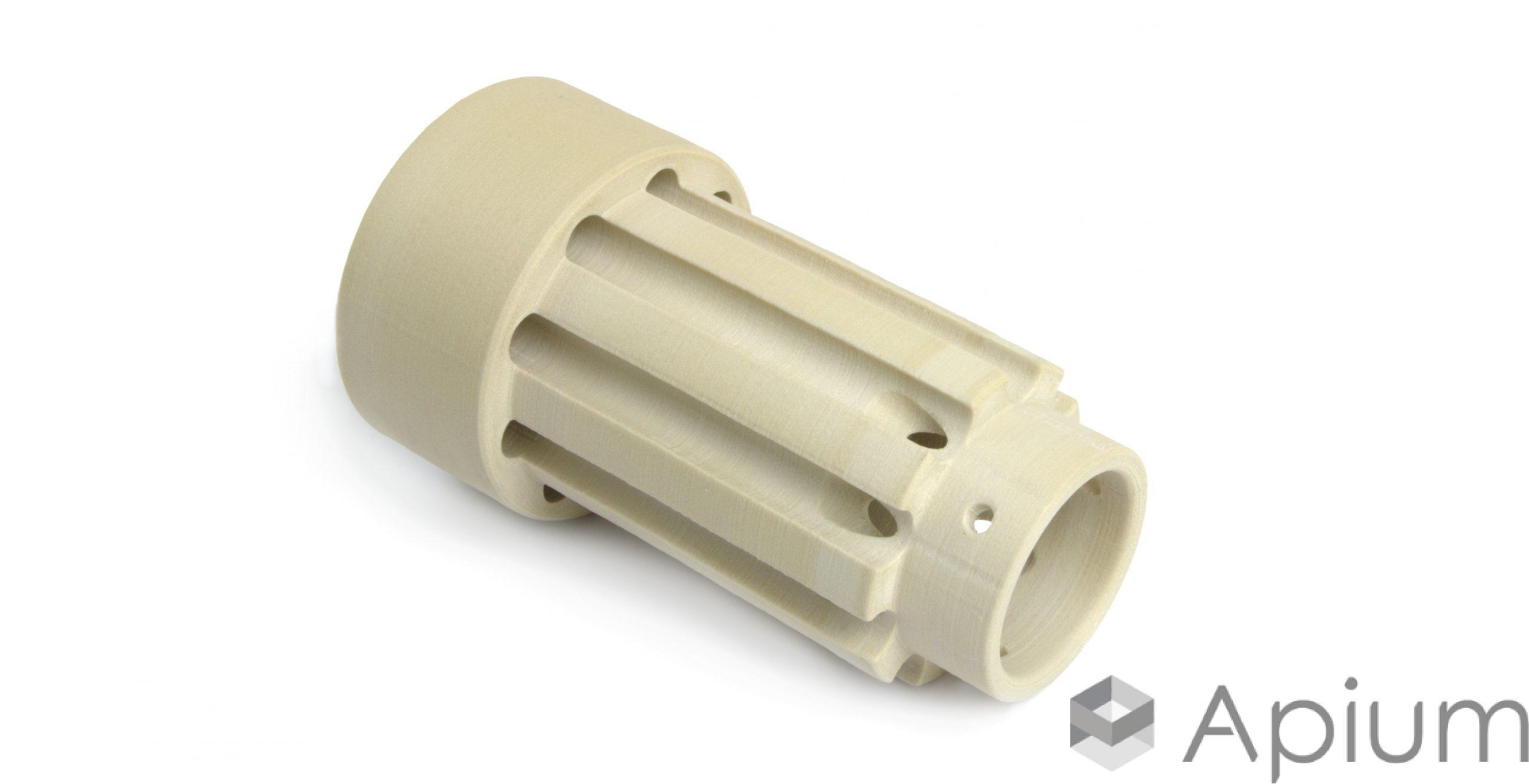

Down Hole Connector

| Process time | Weight | Filament length | Material price |

| 27 h 24 | 201.3 g | 58.11 m | 120.78 € |

Field of application: Oil & Gas industry, cable connection

Characteristic: The down hole connector made of PEEK GFR is intended for use in drill holes. Cables are fed through the holes on the side. The outstanding properties of PEEK GFR in terms of electrical insulation, chemical resistance and compressive strength come into account here.

Apium PEI

PEI 9085 (polyetherimide) is an unfilled engineering plastic with high strength and excellent chemical resistance. It has similar properties to polyether-etherketone, but with lower impact strength and lower thermal resistance. This material is suitable for applications in the aerospace industry, especially due to its excellent flame retardancy.

Topology Optimized Bracket

| Process time | Weight | Filament length | Material price |

| 2 h 10 | 13.1 g | 3.88 m | 3.80 € |

Field of application: Aviation

Characteristic: Thanks to its mechanical and flame-retardant properties, PEI 9085 is a popular material in aviation. In combination with lightweight construction concepts, the weight reduction of additive manufactured components is a further advantage.

Pump Impeller

| Process time | Weight | Filament length | Material price |

| 4 h 05 | 30 g | 9.57 m | 8.70 € |

Field of application: Gases

Characteristic: PEI 9085 is also a temperature resistant material and therefore suitable for use at high temperatures. As an amorphous thermoplastic it is also characterized by the low material distortion after the printing process.

Channel for Liquids

| Process time | Weight | Filament length | Material price |

| 3 h 07 | 7.2 g | 2.27 m | 2.09 € |

Field of application: mechanical engineering

Characteristic: The glossy surface of PEI 9085 results in a beautiful component texture. Therefore the material is also suitable for objects in visible areas.

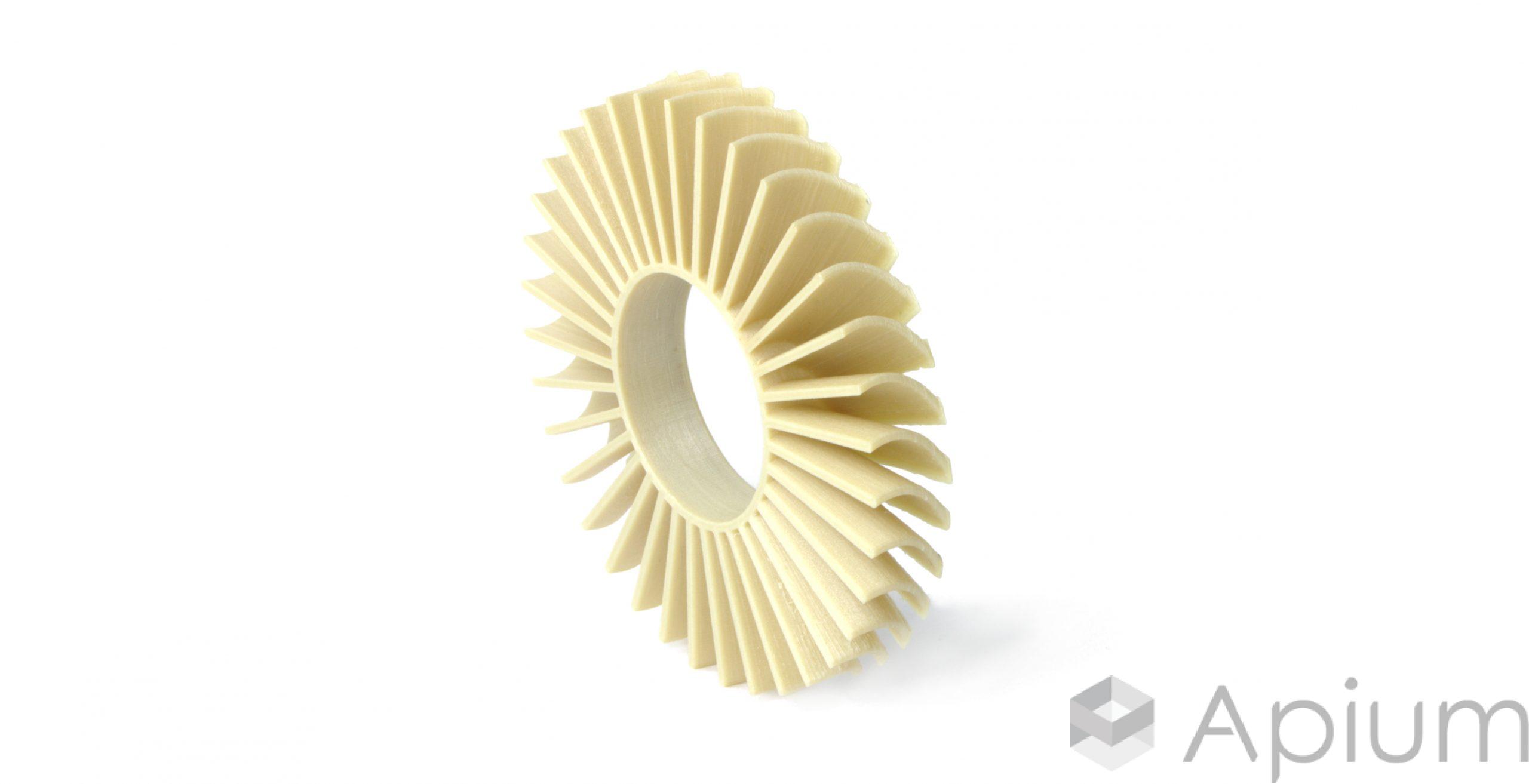

Impeller with Open Blades

| Process time | Weight | Filament length | Material price |

| 4 h 11 | 14 g | 4.41 m | 4.06 € |

Field of application: mechanical engineering, air ducting

Characteristic: Turbine blades are conventionally complex to manufacture. However, this can be achieved quite easily with additive manufacturing. If PEI 9085 is used, these components are also thermally and mechanically resilient.

Turbine Wheel

| Process time | Weight | Filament length | Material price |

| 1 h 46 | 9.4 g | 2.95 m | 2.73 € |

Field of application: mechanical engineering, air ducting

Characteristic: There are almost no limits to the design possibilities of additive manufactured components. The potential of the design can be fully exploited if the right materials are used.

Apium PVDF

PVDF (Polyvinylidene fluoride) is a homopolymer with medium viscosity. Similar to other high-performance polymers it offers stability in the form of thermal, chemical or ultraviolet conditions. This material is thermally resistant/structurally stable up till 149°C and it is almost universally resistant to chemicals and solvents, showing no signs of effect by long-term exposure to ultraviolet radiation.

Pipe Cooling Unit

| Process time | Weight | Filament length | Material price |

| 3 h 01 | 16.3 g | 3.81 m | 8.97 € |

Field of application: Liquids, thermal management

Characteristic: PVDF is one of the most resistant materials when it comes to aggressive media. Combining it with cooling or heating channels to control the temperature of liquids gives you new opportunities in your component creation.

Flat Gasket

| Process time | Weight | Filament length | Material price |

| 5 h 36 | 11.2 g | 2.61 m | 6.16 € |

Field of application: Sealing

Characteristic: The thin layers of at least 50 µm that can be printed, makes the flexibility and thickness PVDF sealings fully adustible. Also the design for the sealings can easily be set.

Impeller

| Process time | Weight | Filament length | Material price |

| 6 h 51 | 20.3 g | 4.75 m | 11.17 € |

Field of application: Pumps

Characteristic: PVDF shows great resistivity to acids. To pump those fluids, creating impellers out of PVDF is an excellent material choice.

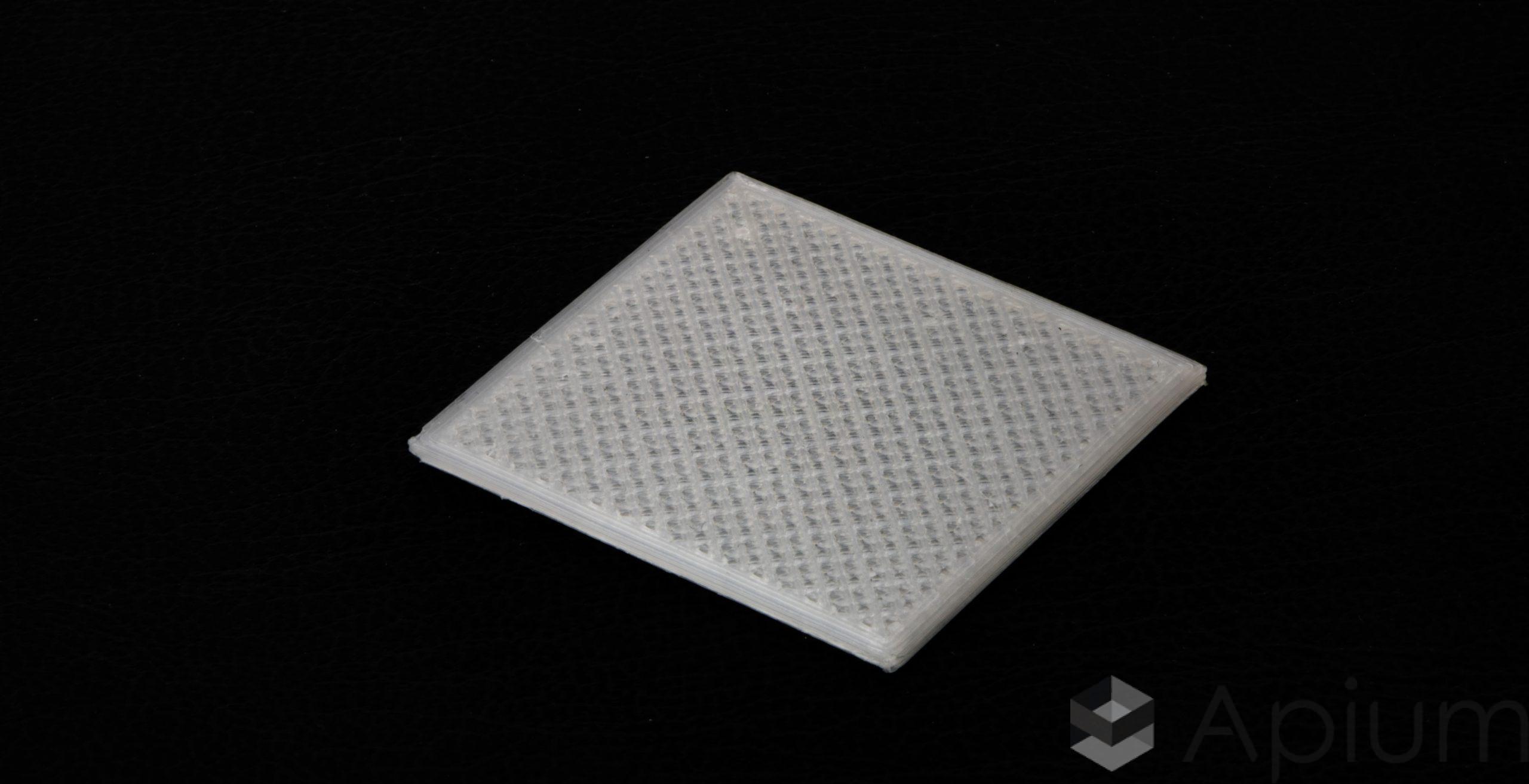

Net / Mesh

Field of application: Filtration

Characteristic: Net structures can designed with a great degree of freedom. If you are looking to create etching masks, PVDF is the right material choice.

Apium PP

Polypropylene is a low melting point thermoplastic with high chemical resistance. It is non-reactive, tough and translucent for low wall thicknesses. It is a popular material which is used mainly in the handling of food, household appliances and fittings.

Bottle

| Process time | Weight | Filament length | Material price |

| 10 h 17 | 11.3 g | 3.55 m | 1.33 € |

Field of application: Preservation

Characteristic: Polypropylen (PP) is an affordable and a chemical resistant polymer. Therefore it is a preferred plastic when it comes to the storage of various materials.

Three Channel Swirl Mixer

| Process time | Weight | Filament length | Material price |

| 11 h 34 | 33.0 g | 10.39 m | 3.89 € |

Field of application: Liquids, Mixture

Characteristic: PP is chemcially unreaktive and exhibits translucent properties. To investigate a mixing procedure, PP is the right choice.

Pipe Cooling Unit

| Process time | Weight | Filament length | Material price |

| 4 h 36 | 14.6 g | 4.59 m | 1.72 € |

Field of application: Liquids, thermal management

Characteristic: PP is not the most heat resistant material. For commoditive temperatures the material might just be sufficient. Its main adavante lies in the non reactiveness combined with its affordable price.

Gasket Solid

| Process time | Weight | Filament length | Material price |

| 8 h 02 | 38.3 g | 12.07 m | 4.52 € |

Field of application: Sealing

Characteristic: Polypropylene in its thermoplastic nature shows a certain toughness which can be adjusted by using additive manufacturing. By setting the infill structure, you can adjust the flexibility of our component by having it more hollow or solid.

Discover the possibilities of additive production with high-performance polymers to secure advantages for your company.