Medical Applications

Application examples in the field of medical technology

Additive manufacturing is the most economical, material-conserving and therefore suitable method of individual single-part production. The bio compatibility of material and machine is assured by standard-compliant processing conditions. The printed products are therefore suitable for implants including class III.

Get inspired by the application examples of additive manufactured PEEK implants and create the designs of tomorrow.

Vestakeep i4 3DF

For medical devices and implants intended for permanent use in the human body (class III), Vestakeep i4 3DF is the appropriate material. Successful suitability according to ISO 10993. Bio compatibility has been proven and cytotoxicity is continuously checked for each delivery. In this way, we would like to ensure maximum traceability and thus maximum safety for your additive-manufactured medical products.

Carpal Bone

| Process time | Weight | Filament length | Material price |

| 1 h 35 | 8.73 g | 2.75 m | 47.14 € |

Macillo Facial Implant (Face)

| Process time | Weight | Filament length | Material price |

| 8 h 20 | 25.8 g | 8.13 m | 139.32 € |

Macillo Fazial-Orbitale Implant (Jaw / Face)

| Process time | Weight | Filament length | Material price |

| 2 h 07 | 15.6 g | 4.91 m | 84.24 € |

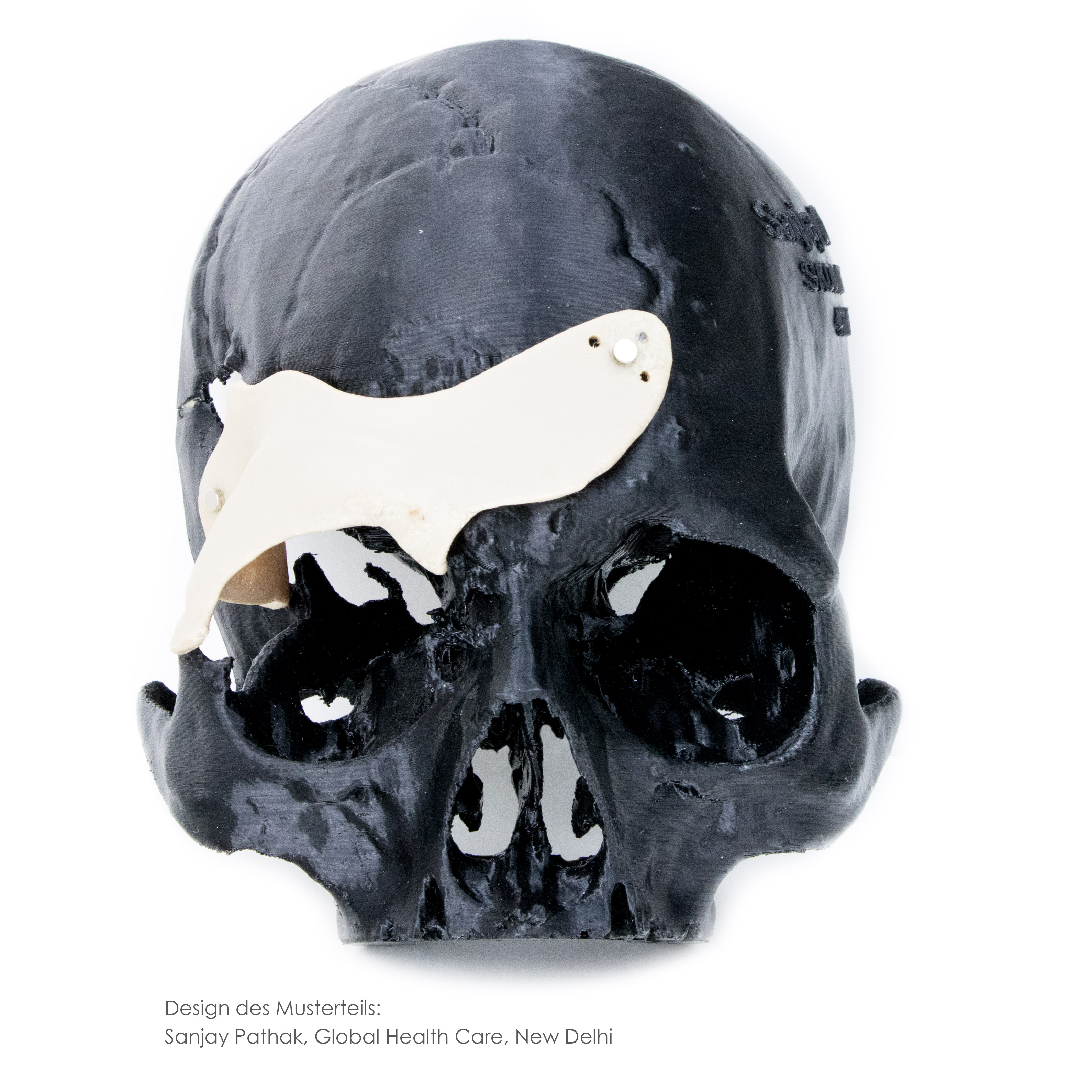

Cranial Implant (Skull)

| Process time | Weight | Filament length | Material price |

| 11h 07 | 84.6 g | 26.65 m | 456.84 € |

Orbital Implant

| Process time | Weight | Filament length | Material price |

| 1 h 55 | 2.3 g | 0.74 m | 12.42 € |

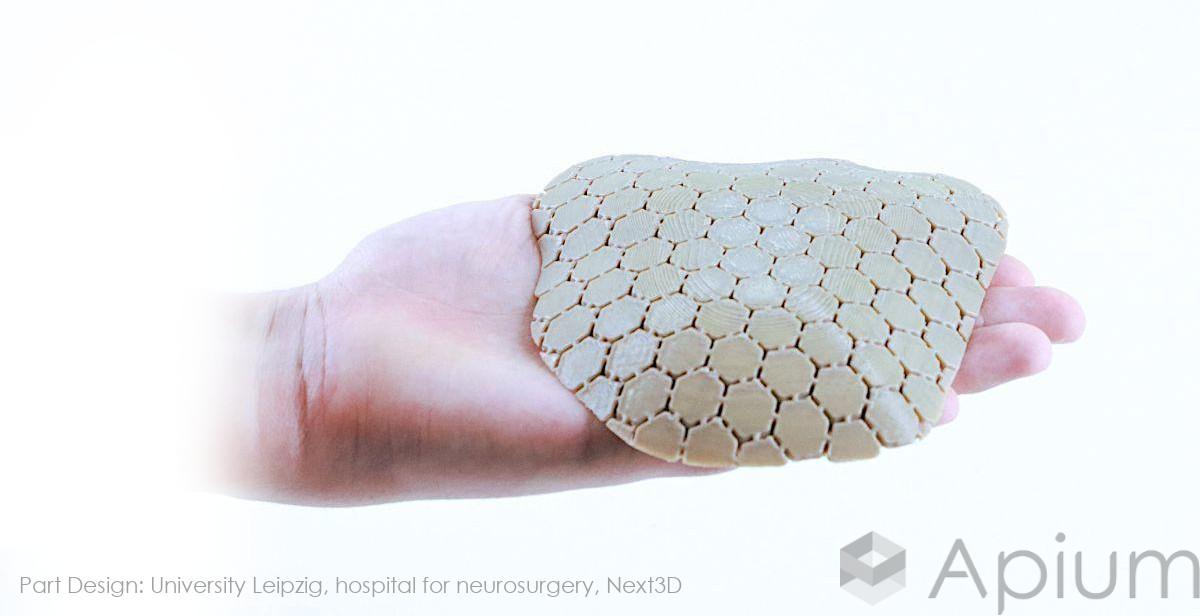

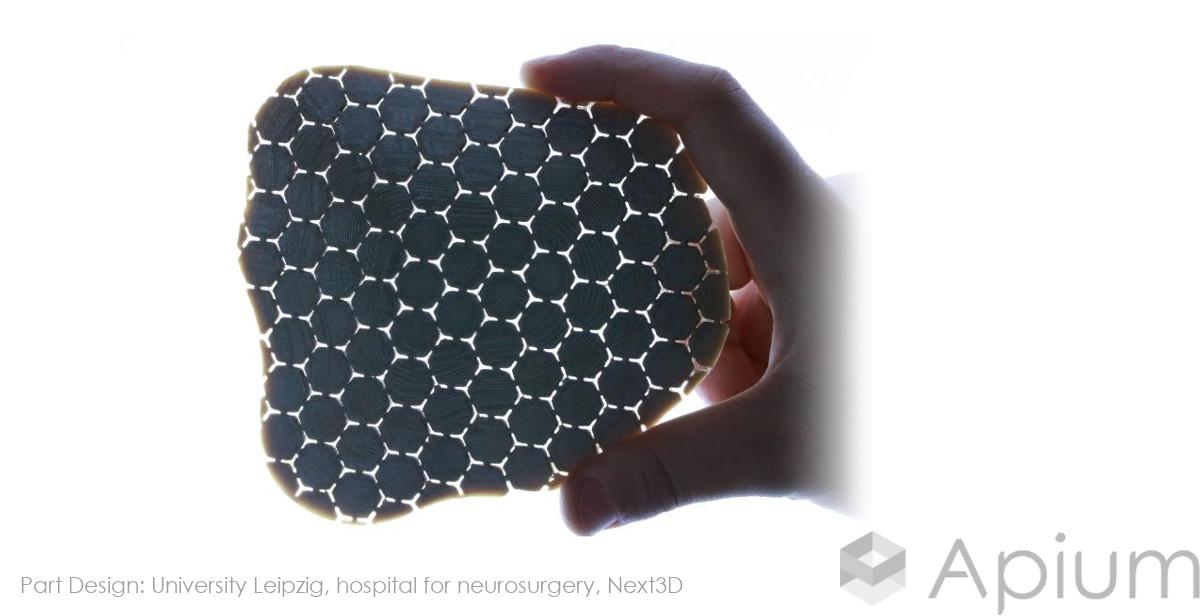

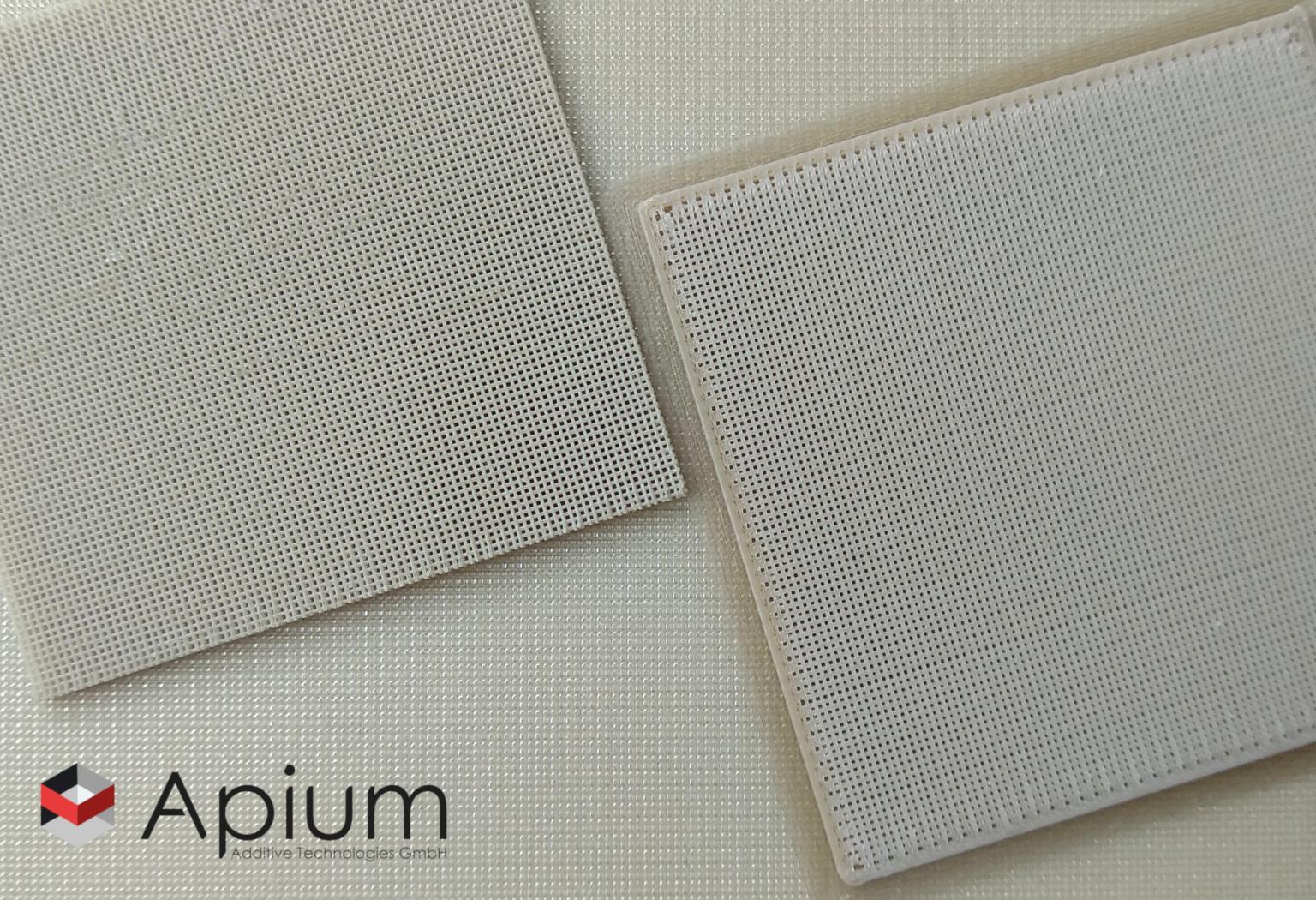

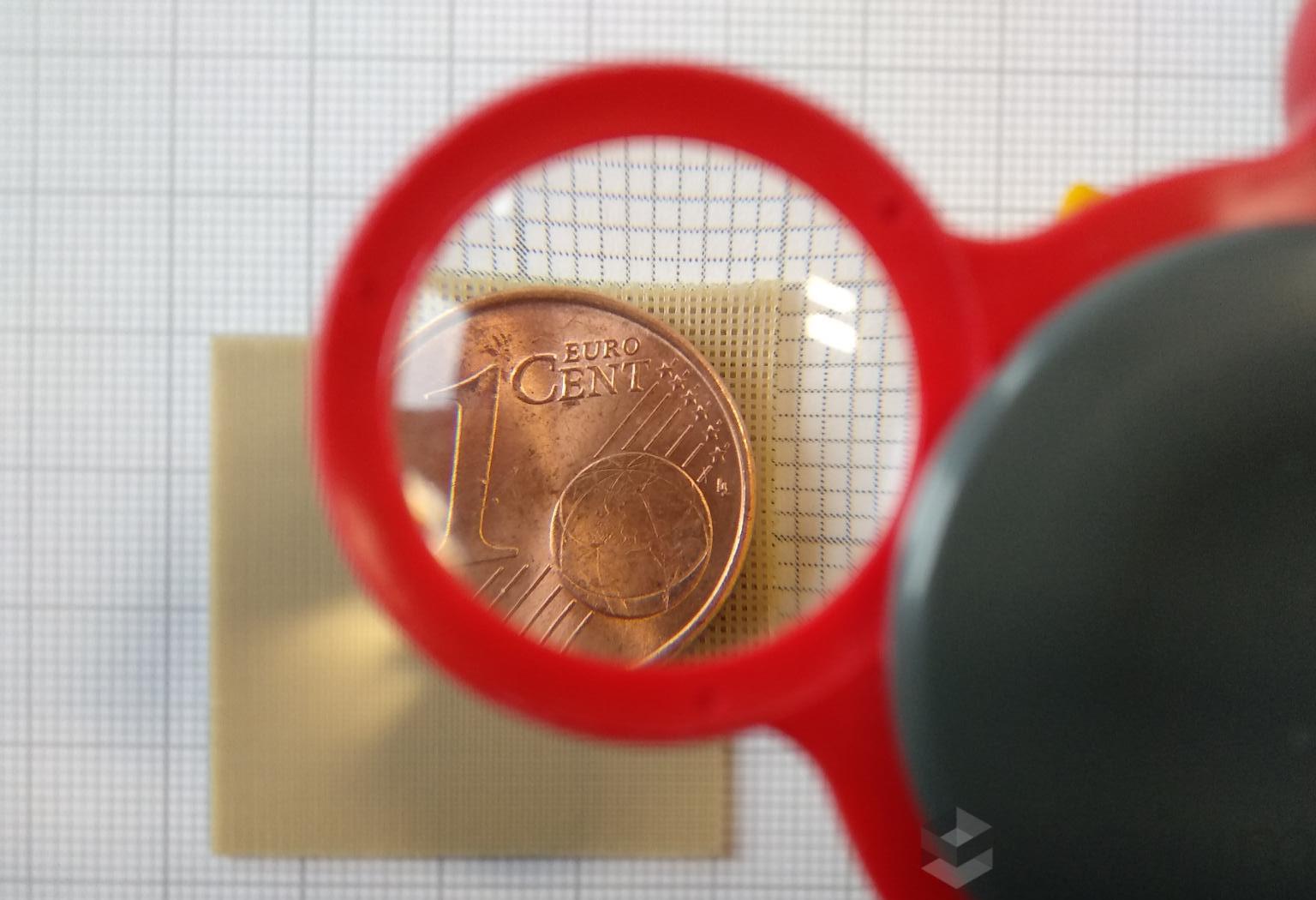

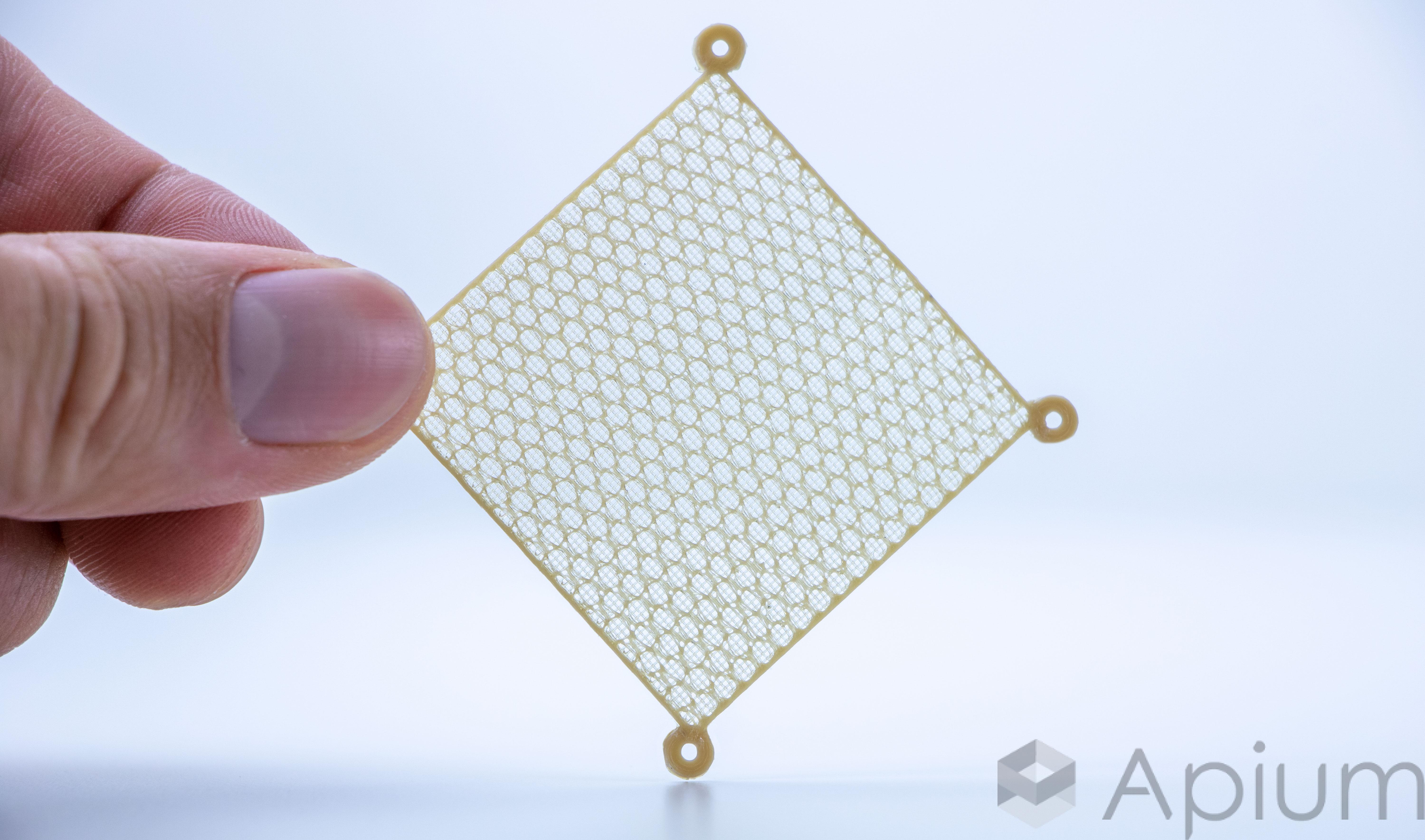

Net Structures

| Nozzle diameter | Extrusion / line width |

| 0.2 mm | 0.3 mm |

Discover the possibilities of additive production with high-performance polymers to secure advantages for your company.