MATERIALS FOR 3D PRINTING

APIUM HIGH-PERFORMANCE MATERIALS

Apium enables the highest part quality in the additive production of high-performance polymers.

High part quality starts with the material. Apium filaments are the best choice for industrial and medical applications.

Top Overall Material Quality

The cooperation with the industry leader Ensinger and our aspiration for highest quality guarantees the purity and compliance with high dimensional tolerances of our filaments and high performance materials.

Compatibility & Quality Management

Our focus and the development of own high-performance materials guarantee that our 3D printers are developed in the meaning of our materials. This ensures compatibility and highest quality of printed components.

Open Material Selection

In order to support the idea of research and development, you have the opportunity to process third party filaments using Apium P Series. Our experts will be happy to advise you and find the right material for your individual requirements.

Apium PEEK 450 Natural / Black / Blue

PEEK (Polyetheretherketone) is a semi-crystalline thermoplastic which is ideally suited for applications with thermal, chemical and mechanical exceptional conditions. It allows users to reduce overall weight, extend life time and thanks to the Material Extrusion it increases design freedom.

Apium PEEK 4000

The Apium PEEK 4000 is characterized by its improved layer adhesion and the resulting improved mechanical properties. The filament is not a mixture but a pure PEEK as known from semi-finished products and granulates, which however achieves better processing results.

Apium PEEK CFR

The combination of PEEK and 30% carbon fibers provides Apium PEEK CFR enhanced thermal and mechanical properties as well as high stiffness. Its improved thermal conductivity properties allow end-users to use this material especially in systems where thermal management plays a critical role, such as heat dissipation in microprocessors and other electronic systems.

Apium PEEK CFR 4000

Being one of few suppliers for 30% carbon fiber content reinforced materials, we now are able to offer the improved version Apium PEEK CFR 4000. Based on the advantages of our Apium PEEK CFR, it offers enhanced layer adhesion and mechanical properties.

Apium PEEK GFR

PEEK GFR (Glass Fibre Reinforced) is a compound combining the great chemical and thermal properties of PEEK with the high stiffness of glass. This combination provides components with high dimensional accuracy and natural PEEK colored aesthetics.

Apium PEI 9085 (ULTEM) Natural

PEI 9085 (Polyetherimide) is an unfilled engineering plastic with high strength and broad chemical resistance. It shows similar properties to Polyetheretherketone, but it is relatively cheaper with low impact strength and lower thermal resistance. This material is especially attractive for applications in the aircraft industry due to its excellent flame retardancy.

Apium PVDF

PVDF (Polyvinylidene fluoride) is a homopolymer with medium viscosity. Similar to other high-performance polymers it offers stability in the form of thermal, chemical or ultraviolet conditions. This material is thermally resistant/structurally stable up till 149°C and it is almost universally resistant to chemicals and solvents, showing no signs of effect by long-term exposure to ultraviolet radiation.

Apium PEKK Amorph

Apium PEKK Amorph is semi-crystalline by nature but has been designed to stay amorphous if desired. It shows a great layer adhesion and thanks to our Temperature Management System, we are even able to print it semi-crystalline. This means you can choose between amorphous toughness and crystalline strength.

Apium PP

Polypropylene is a low melting point thermoplastic with high chemical resistance. It is non-reactive, tough and translucent for low wall thicknesses. It is a popular material which is used mainly in the handling of food, household appliances and fittings.

Apium ABS ESD

Electrostatic Discharge is an important property if you are in an environment where you need to avoid any damage on electronic components. Apium ABS ESD comes in black colour and the printing behaviour is very good: you have tight dimensional tolerances and can create fixtures for your electronic assembly.

Apium Smart ABS

Apium Smart ABS is an inexpensive and dimensionally stable polymer which is perfectly suitable for the production of covers, housings and components which are neither exposed to high chemical nor high mechanical stress.

Apium Premium PA CFR

Apium Premium PA CFR is a carbon fiber-reinforced plastic modified to be adapted by Material Extrusion Technology. This material is more attractive for applications in the automotive sector due to its excellent wear resistance and printability.

Apium PA6 GFR

Apium PA6 GFR contains 30% special glass fibers developed for filament manufacturing and 3D printing. It has less deformation compared to pure PA6, which makes it with excellent layer adhesion. With its high wear and chemical resistance and high stiffness and strength, it is perfect for various applications, e.g. in transport or industrial tools.

New materials under development

Be the first to know about new product releases. Subscribe for Apium News.

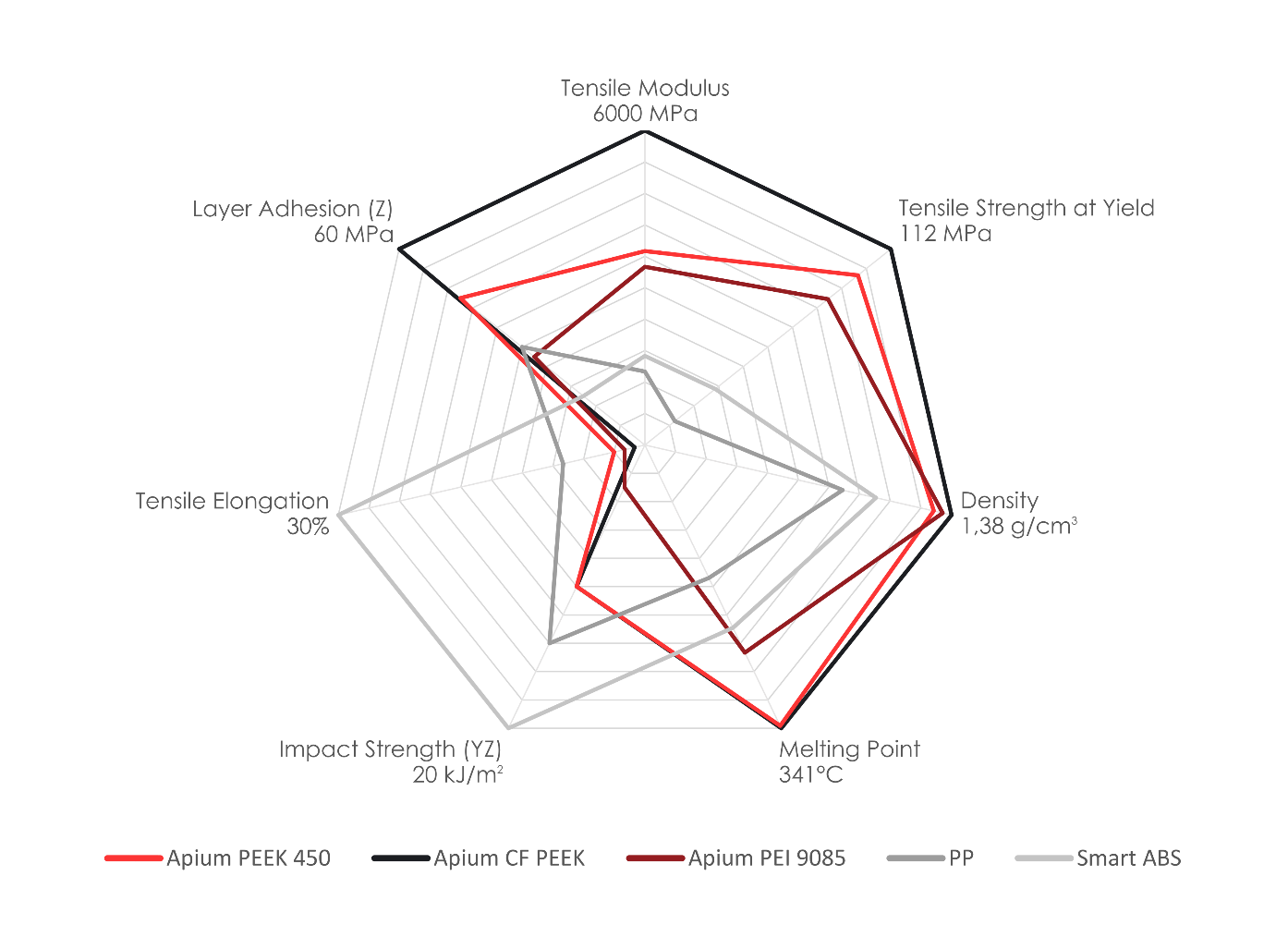

Material Property Comparasion

Explore our innovative 3D printing technology to grow your business with Additive Manufacturing of high performance polymers.