CASE STUDY

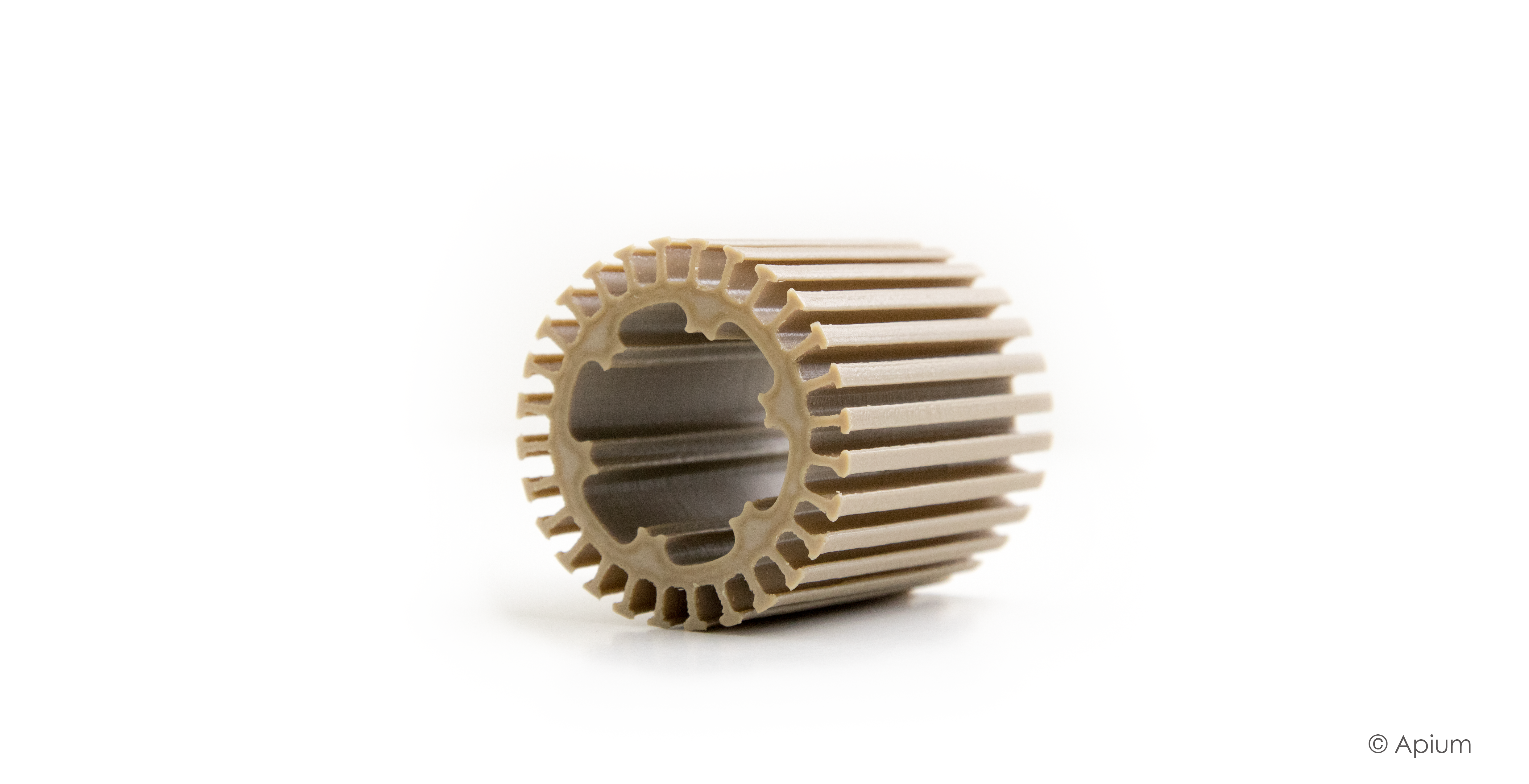

Chemical Resistance of 3D Printed PEEK Parts

A wide variety of engineering fields use PEEK due to its excellent thermal, mechanical and chemical properties. The different grades of PEEK exhibit non-identical properties. Additionally, actual part properties may change due to processing method. Therefore, achieving successful results with 3D printing highly depends on three factors:

- Temperature management system of the 3D printer

- The filament quality

- Process stability

Read our case study to learn more about the chemical properties of 3D printed PEEK parts.

PLEASE COMPLETE THE FORM BELOW

TO DOWNLOAD THE CASE STUDY

Explore our innovative 3D printing technology to grow your business with Additive Manufacturing of high performance polymers.