APIUM MAKES IDEAS HAPPEN

Apium Additive Technologies GmbH is a technologies based company located in Karlsruhe (Germany) that provides solutions for processing high performance polymers with Fused Filament Fabrication 3D printing technology. The company provided the first commercially available PEEK filament and developed the first filament based FFF 3D printer optimized for processing high performance polymers used in industrial applications.

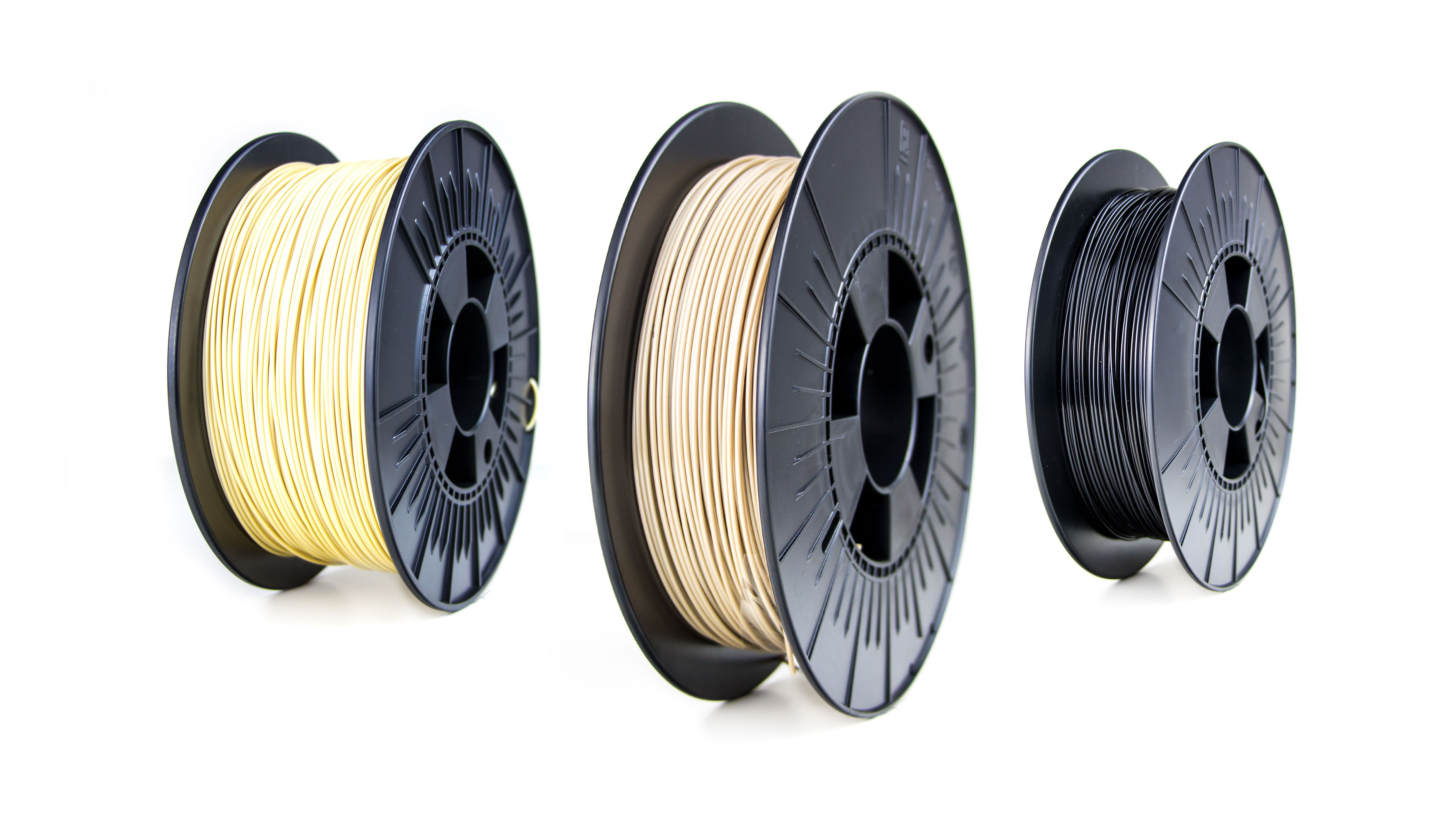

MATERIALS

High part quality starts with the material. Apium filaments are the best choice for industrial and medical applications.

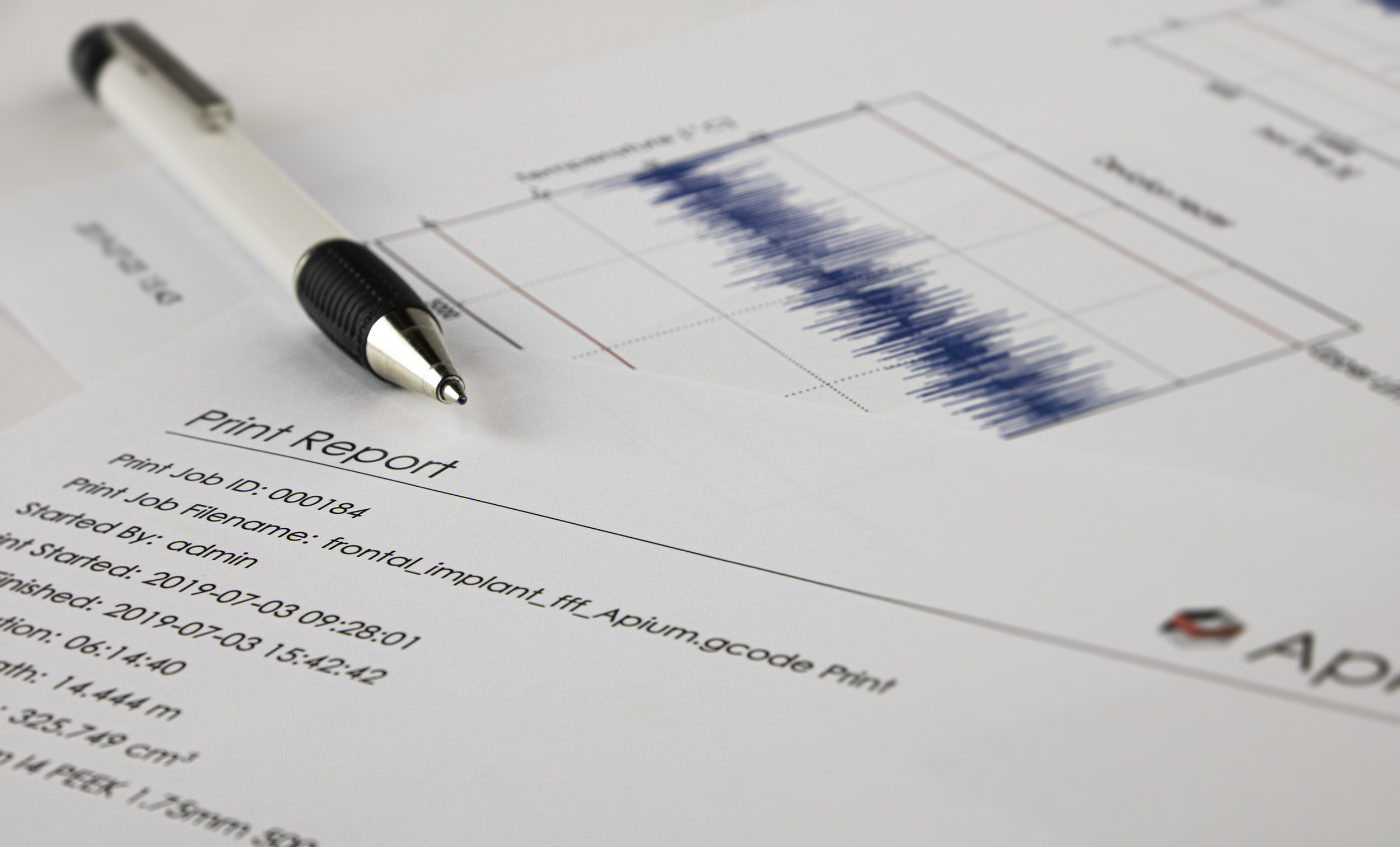

SERVICES

Avoid trial and error learning and save time and costs with our customer experience oriented Service Center.

KNOWLEDGE

Download data sheets and case studies of our 3D printers and filaments.

WE ARE THERE FOR YOU

With strong partnerships for innovative outputs, Apium wants you find your local reseller and test Apium’s technology on site and in your language.

SOME OF OUR PARTNERS

INDUSTRIAL 3D PRINTING NEWS

MEDICAL 3D PRINTING NEWS

Discover the possibilities of additive production with high-performance polymers to secure advantages for your company.