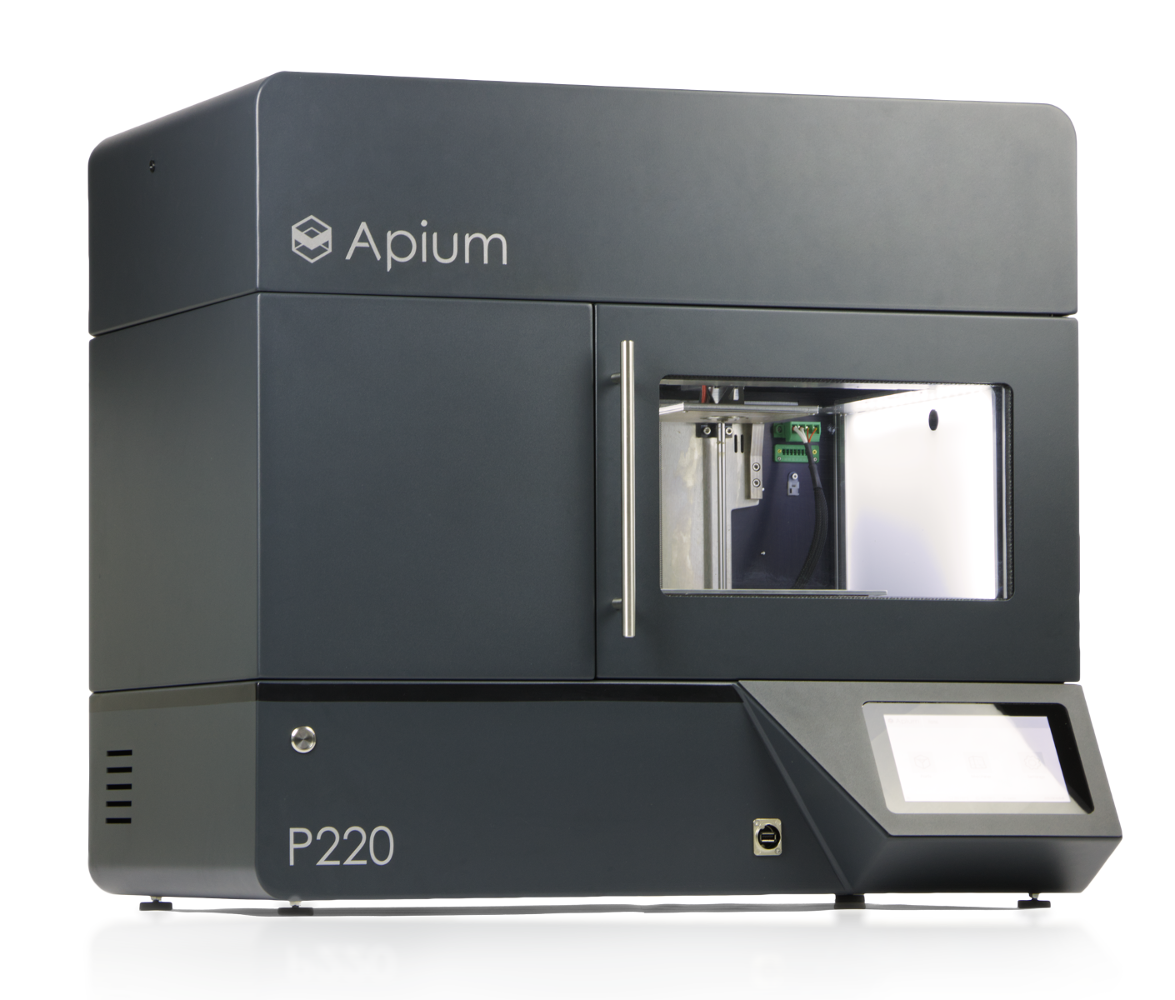

Apium P220

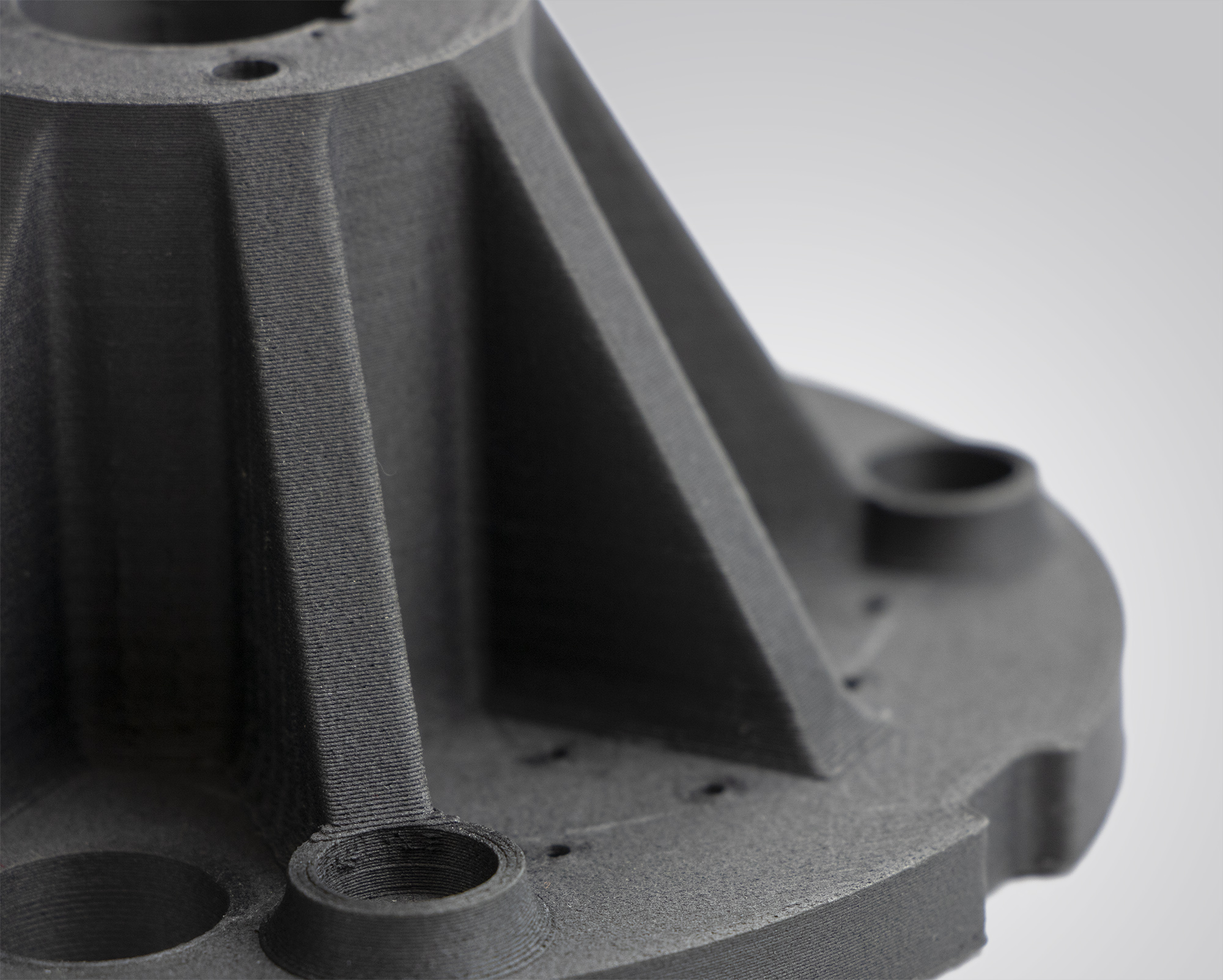

An industrial 3D printer for highest component quality in high-performance plastics

3D printing of PEEK | CFR PEEK | PEKK | PEI | …

The P220 is the only printer that can print both pure PEEK in high crystallinity and carbon fiber reinforced PEEK with up to 30% fiber content.

Special polymers require special processing

High-performance plastics have exceptional mechanical and thermal properties. However, there are also some challenges when printing these materials.

What is my goal?

A fully crystallised part, good surface quality and good layer adhesion.

What is needed to achieve this?

In order to achieve a fully crystallized component and good adhesion of the layers, more energy is required in the topmost layers than with conventional materials. This additional energy in the form of heat can be introduced in various ways. The three following methods are the most commonly used:

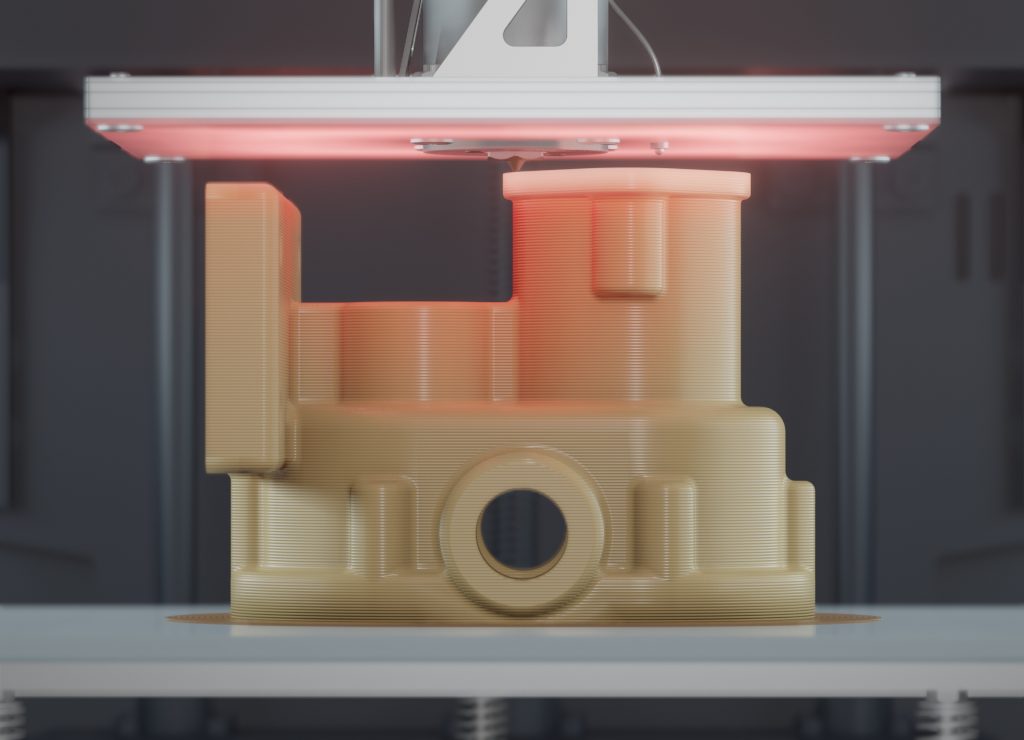

Apium Adaptive Heating System

(Apium P220)

Energy is only introduced where it is needed – in the uppermost layers. We achieve this by installing a zone heater just above the printing surface, which forms a hot air film.

Why this solution? We achieve a completely crystallized component with simultaneously very good surface quality and good layer adhesion. No other method can meet these three goals simultaneously. Furthermore, our process is extremely agile and energy-saving due to the relatively small heated area.

Surface quality | Tolerances

For a good surface quality and tight tolerances it is important that the part remains stiff in the lower areas to avoid micro movements during printing. This stiffness is achieved by staying just below the softening temperature (Tg) of the printing material.

Only in the uppermost layers are the temperatures above Tg. This is required for good layer adhesion.

Compared to a space heater, the zone heater is very agile and can be quickly adjusted to any desired condition. This allows us to print small details without smearing them.

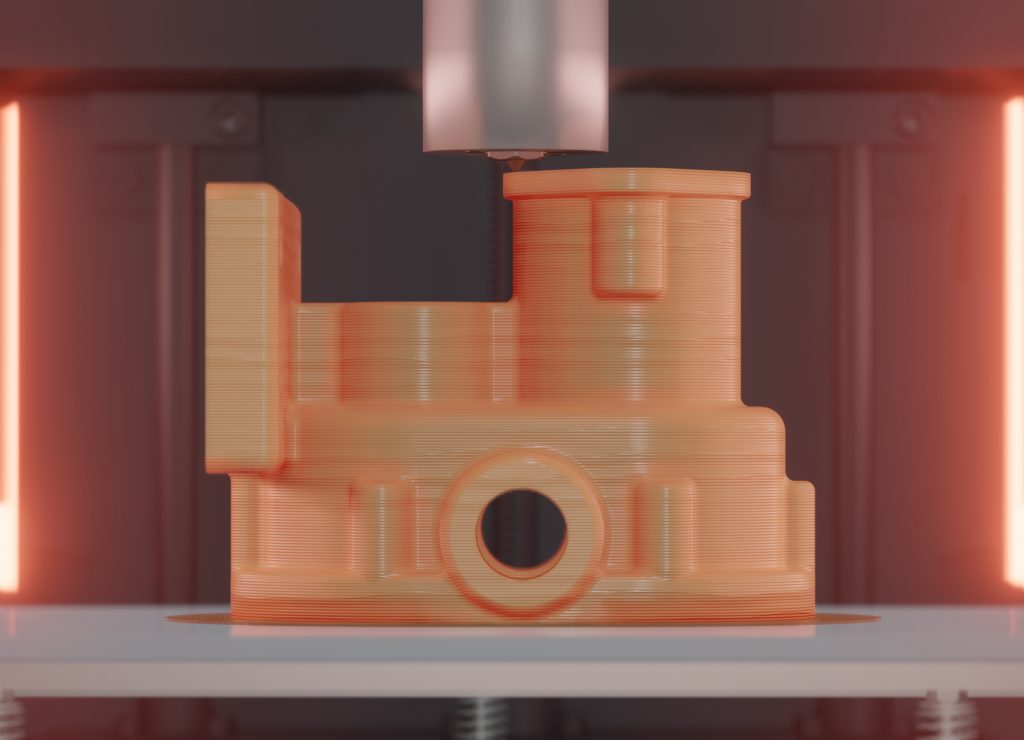

Heated build volume 120°C – 220°C

(3D printers in high price ranges)

The entire build volume is heated to temperatures of up to 220°C. The high temperatures enable a completely crystallized component and good layer adhesion. However, the surface quality of this process is poorer.

The large thermal mass, which must be heated before each printing process, leads to long heating times and high energy consumption. In addition, the high temperatures in the installation space have a negative effect on bearings and other mechanical components.

Surface quality | Tolerances

The temperatures in the entire part are far above the softening point (Tg) of the component. As a result, the material loses rigidity and the movements of the print head generate micro movements. This leads to a loss of surface quality and tolerances.

Furthermore, local overheating can occur, which causes smearing of small details.

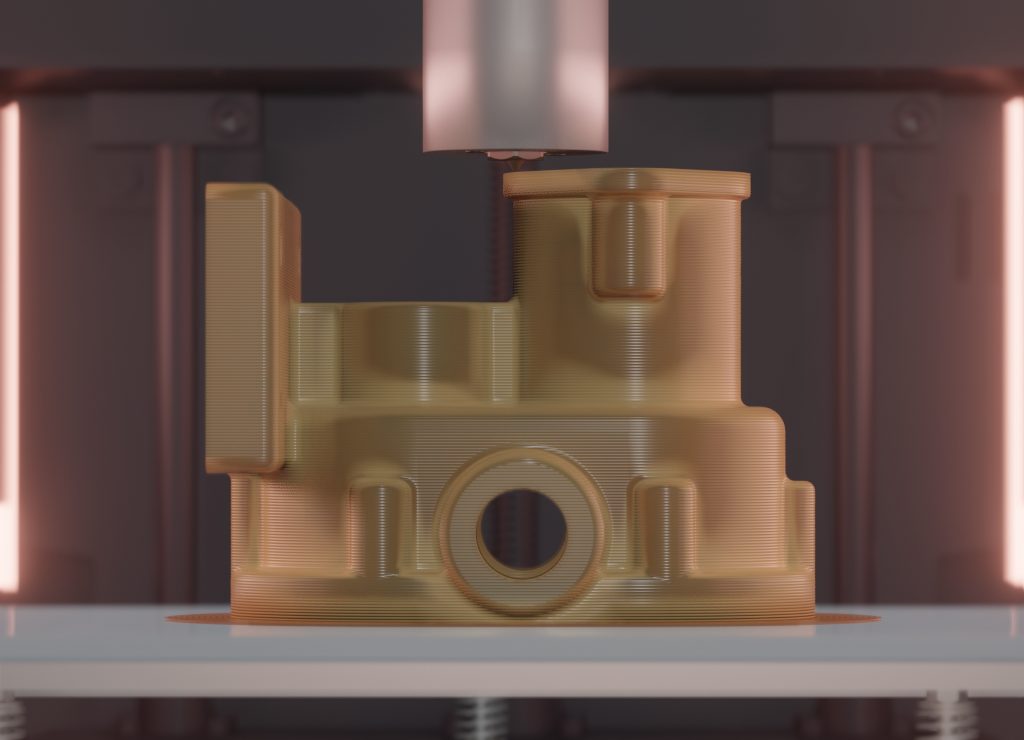

Heated build volume 60°C – 120°C

(3D printers in lower price ranges)

Here again, the entire installation space is heated up to 120°C. Due to the significantly lower temperatures, the part cools down too quickly and thus cannot crystallize completely. This results in amorphous phases in the component. These can be recognised by their dark discolouration.

These phases have a negative effect on the mechanical, chemical and thermal usability of the components and must be post-crystallized by a additional work step.

Surface quality | Tolerances

After the printing process, the part is annealed in an oven. This results in a transformation of the amorphous phases into a crystalline structure.

This process causes a change in density and results in distortion in the component. This effect is particularly strong with more complex geometries.

Poor dimensional accuracy cannot be avoided with this method.

The Apium Adaptive Heating System combines the advantages of the other two methods. It only heats in those areas where necessary. The other areas remain colder to ensure sufficient stiffness. This leads to a best possible component quality.

| Apium Adaptive Heating System | Heated build volume – 120°C to 220°C | Heated build volume – 60°C to 120°C | |

| Energy consumption | + | – | – |

| Layer adhesion | + | + | + |

| Surface quality | + | – | + |

| Tolerances | Form accuracy | + | + | – |

| Printing of small details | + | – | + |

| Time consumption (heating phase, additional steps) | + | – | – |

P220 Features

Best Part Tolerances

The patented Adaptive Heating System analyses the printing geometry and adjusts the heating power to achieve always an optimum energy input. Without thermal post-treatment, you get even finer details and compliance with narrow tolerances. Due to the high stiffness and strength, even embossing dies for aluminium and stainless steel sheets can be printed.

New extrusion technology

Our extruder was developed with flexibility and robustness in mind. The feed force, which is four times higher than that of the previous model, makes it possible to process fibre-reinforced high-performance polymers with a high percentage of filling. The specially designed filament guide automates the loading process.

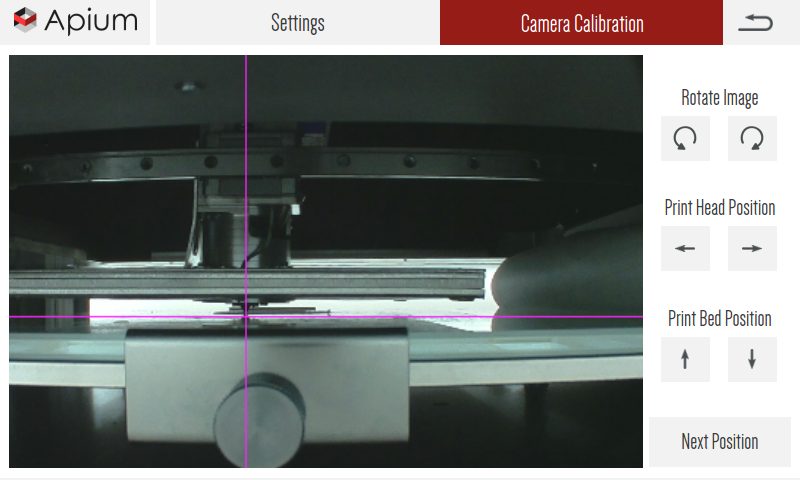

Monitored Printing Process

By integrating a camera system, temperature recording and the use of servo motors, the printing process is continuously monitored. This allows the printer to intervene independently when deviations occur.

Reproducibility

Integrated calibration routines guarantee consistent part quality. The software automatically notifies you of any maintenance work and guides you step-by-step through the procedures.

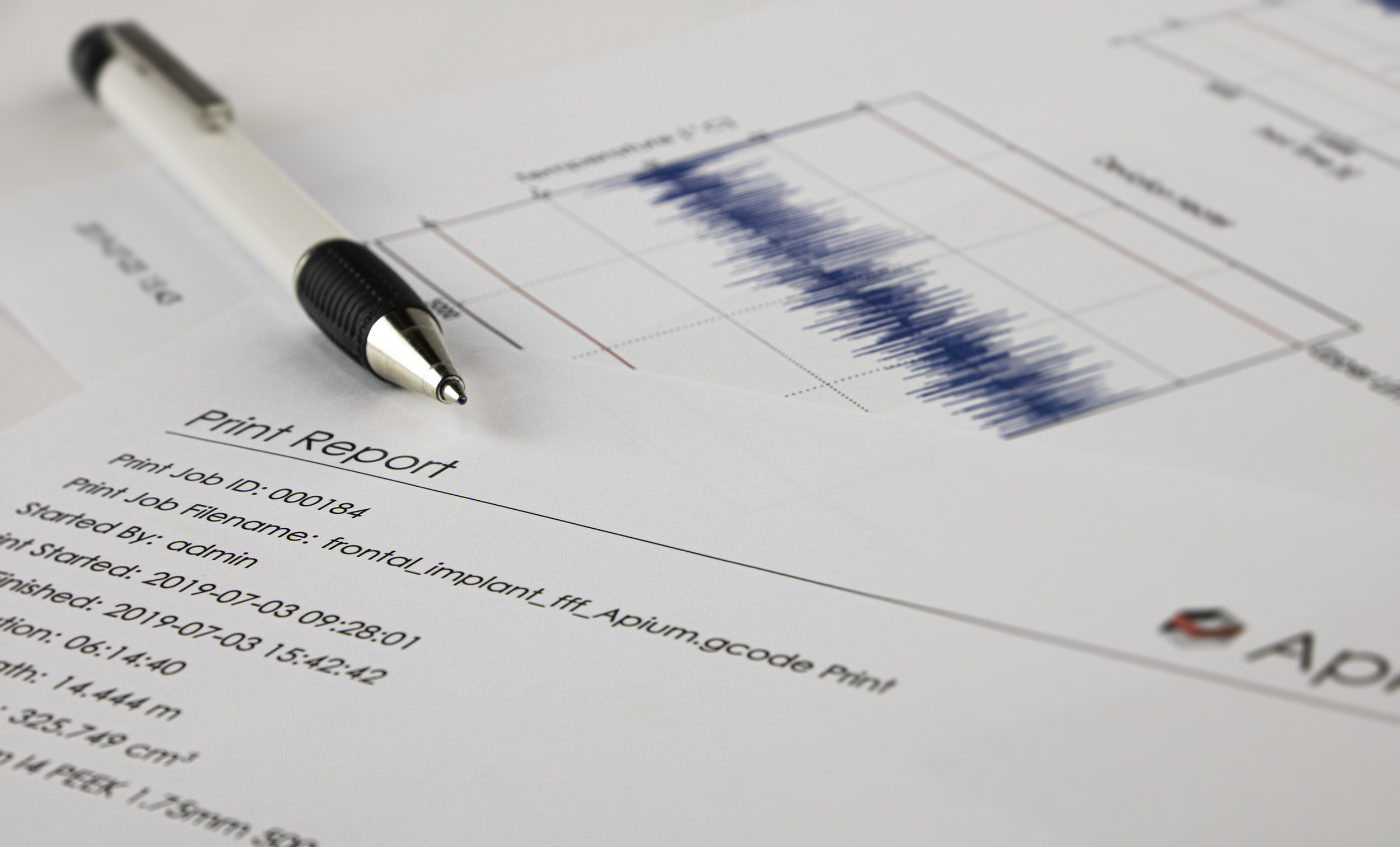

Documentation & Safety

All the important parameters of a printing process are automatically made available in a PDF protocol. The integrated user management prevents unwanted access. For your data security, we have decided against cloud based solutions.

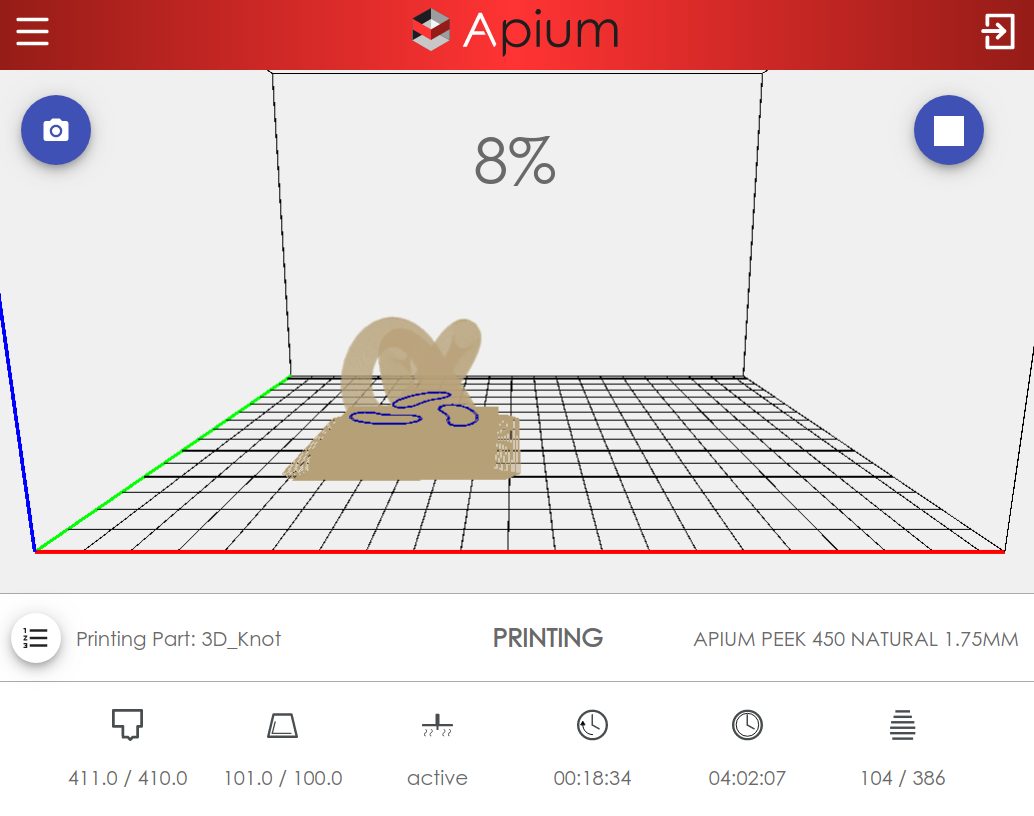

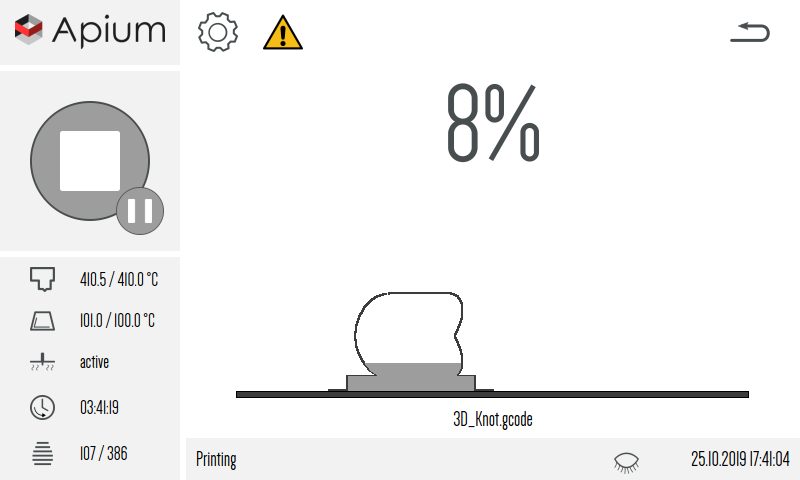

Integrated Software

The control software is specially adapted to our printer hardware and optimized for processing high-performance polymers. An intuitive user interface allows easy operation of the printer. You can manage print jobs and check the status of the printer at any time.

Innovative Materials

The open system allows the use of other materials that are not available in our product portfolio. The P220 also allows the processing of metal filled filaments which can be sintered.

Technical Support

Our service department will train you in the handling of your printer. We will be happy to answer any questions you may have about the printer and other challenges of 3D printing of high performance polymers.

Build Size

205 x 155 x 150 mm

Printer size

850 x 685 x 675 mm

Nozzle Diameter

0.2 – 0.8 mm

Layer Thicknesses

0.05 – 0.6 mm

Wall Thickness

> 250 µm

Printhead-Temperature

Up to 540°C

Adaptive Heating

Up to 180°C

Printbed-Temperature

Up to 160°C

Print Bed Material

Borosilicate glass

Noise Emission

< 55 dB(A)

Material Extrusion (FFF) 3D Printing Technology

Material Extrusion 3D Printing (also known as Fused Filament Fabrication or Fused Deposition Modelling) is a 3D printing technology which is used for processing of filament form thermoplastic materials into three dimensional objects. The filament is fed from a large coil, through a moving gear system (extruder) into a heated mechanically translating print head and then extruded through a nozzle onto a surface. Subsequent deposition/extrusion of material onto the surface in a layer by layer approach results in the creation o the 3D object. The entire printing process is computer controlled ensuring that the necessary process control for high quality objects is realized.

Software is a strength of Apium

Software is one of Apium’s core competencies. With the user interface on the printer touchpad, Apium provides the user with simple and efficient operation. Special service and maintenance functions facilitate daily use of the printer and allow detailed access to all settings. The web interface application makes it easy to monitor printing processes with the integrated camera from a remote workplace and manage the printer via the network.

Frequently Asked Questions

Which materials does Apium P220 support?

Apium P220 Series supports a wide variety of amorphous and semi-crystalline thermoplastics from ABS, PP, PVDF, PEI, PEEK, Carbon Fiber Reinforced PEEK to metal containing compounds such as Stainless Steel (316L). The system allows end users to print their materials of choice.

What is the geometrical challenge capability of Apium P220?

The advanced parameter control enables varied print parameters for challenging geometries in a single part. This unique capability overcomes most geometrical challenges.

Does Apium P220 provide material based optimal process parameters?

What can Apium P220's extruder technology do?

Apium`s advanced extruder technology enables processing of reinforced, compound materials as well as pure materials. Our Advanced extruder can process materials containing higher proportions of carbon fiber or glass fiber such as 30% Carbon Fiber Reinforced PEEK.

Can I have training and service customized for my application area?

Apium leads in the field of Material Extrusion 3D printing of high performance polymer based materials. The experts at Apium will guide you through your specific application and business requirements. We transfer our knowledge in additive thinking and improve the application’s design, performance and printability. Avoid trial and error learning and save time and costs with Apium Trainings.

How can I procure Apium P220 series?

How can I procure Apium Filament Dryer?

Along with the Apium P220 Series 3D printer, Apium also delivers the Apium Filament Dryer. The dryer reduces moisture related defects and significantly increases print success rate.

Straight to your own Apium P220 Series

Influence of Printing Parameters on Tensile Strength and Fracture Toughness in 3D Printing PEEK

In a study published by Springer, authors M. Refat, E. Zappino, and A. Pagani have meticulously explored the intricate dynamics between fused filament fabrication (FFF) parameters and their impacts on the mechanical behaviors of 3D-printed PEEK, utilizing the Apium...

Apium P220 is amongst the top best professional 3D printers (PEEK and Ultem™)

Aniwaa chooses Apium P220 amongst the best professional 3D printers for the materials PEEK and Ultem™. With a monthly visit of over 200,000 guests, Aniwaa is the largest comparison website for professional 3D printers and emerging technologies. Every year, the online...