Chemical Resistance of FFF 3D Printed PEEK Parts

Discover the benefits of 3D printing with real-world cases from industry and research.

A wide variety of engineering fields use PEEK due to its excellent thermal, mechanical and chemical properties. The different grades of PEEK exhibit non-identical properties. Additionally, actual part properties may change due to processing method. Therefore, achieving successful results with 3D printing highly depends on three factors:

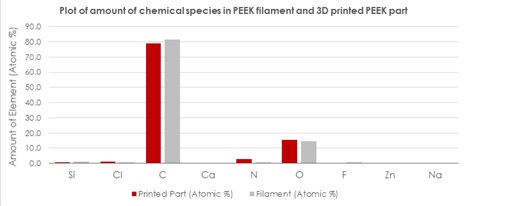

Elemental Analysis on 3D Printed PEEK Parts

The tests were performed using an X-ray Photo Spectrometer (XPS) on Apium PEEK 450 Natural filament as 3D printed parts from Apium P Series 3D printers. XPS analysis allows for the determination of the chemical species within the first 10 nanometre from the surface of the tested sample. This spectroscopy method is highly surface sensitive. The elemental content also accounts for the case where the element exists in its oxidation state.

A summary of the test outcome is indicated in the diagram where it can be seen that within the margin of error the filament and the 3D printed parts quantitatively share a similar chemical composition. This is a clear experimental demonstration that the PEEK filament material processed with the Apium 3D printer is not chemically altered by the printer. Likewise no contaminant or stray material quantifiable by the XPS tool exists in the printed part.

PEEK’s Usage for its Chemical Resistance

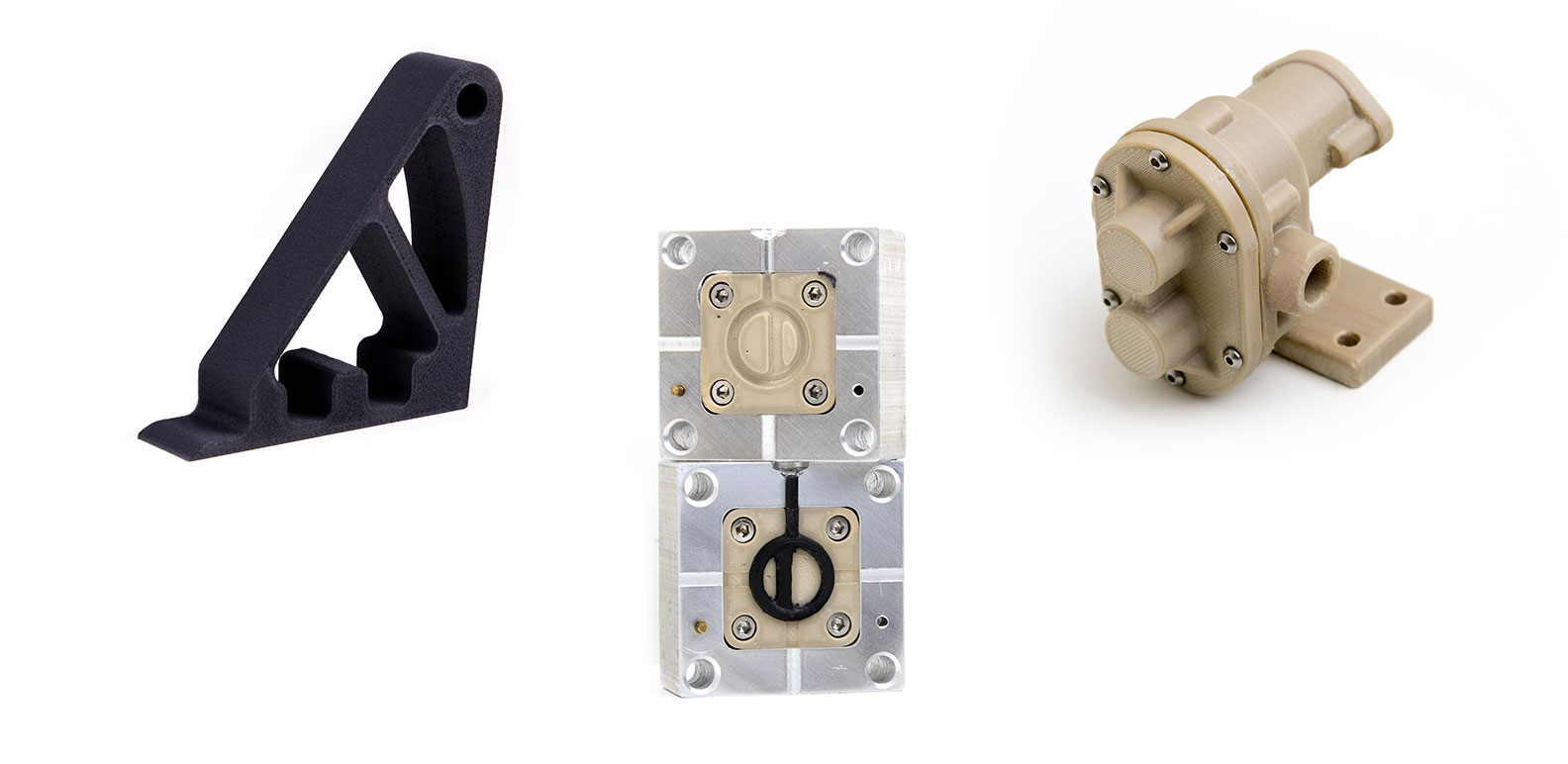

PEEK can be used in very demanding applications as replacement of metal. Most notably aerospace, automotive and chemical sectors prefer PEEK because of its strength, durability and chemical resistance. It exhibits excellent resistance to a wide range of organic and inorganic chemicals.

Key Applications

– Position Units

– Seals

– Bearings

– Washers

– Fasteners

– Various active components in applications such as:

– Transmission systems

– Braking System

– Air-conditioning Systems

Chemical Testing of 3D Printed PEEK Parts

The chemical resistance of each polymer is mainly determined by the chemical structure of the material and the strength of the weakest link in this specific structure. Because of this, different processing methods might affect the chemical resistance of a polymer. A chemical test is conducted on 3D printed PEEK parts to examine the changes in chemical properties.

Test specimens of Apium PEEK 450 Natural were immersed in different chemicals at constant room temperature 24,5 °C for a minimum of 7 days. In the first step, chemical compatibility was assessed via weight or dimensional changes, physical degradation and discoloration.

Compatibility is classified into R, LR or NR. The interpretations of classification are as follows:

R – Good Restistance

LR – Limited Resistance

NR – Not Recommended

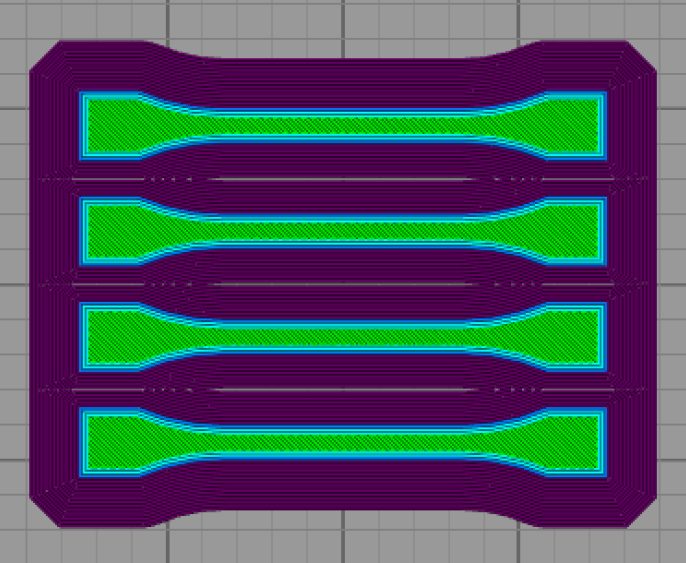

Specimen standard used: DIN EN ISO 527-2 2012-06_type1BA

Layer heights (LH) (mm) tested:

o 0.1

o 0.15

o 0.2

Infill Rate: 100%

Organization of the tensile test (TT): A set of three samples from each test condition is used to check the chemical resistivity.

| Chemical | 24°C (75.2°F) |

| Brake Fluid | R |

| Screenwash Fluid | R |

| Air Conditioning Fluid | R |

| Disinfection Fluid | R |

| Transmission Fluid | R |

| Propylenglykol 99,5% | R |

The test results have shown the following:

- No discoloration

- No peeling or delamination in the surface

- No weight change

- No dimensional changes

occurred on sample.

Compatibility is classified into R, LR or NR. The interpretations of classification are as follows:

R – Good Resistance

LR – Limited Resistance

NR – Not Recommended

Are you interested in more information? Contact us!

Subscribe for Apium News

Every month we inform you about our latest developments, 3D printing and high performance polymers.