APIUM SHOP

PRODUCTS CATALOG

Apium ensures that all the products are of the highest quality

Our product catalog consists of filaments, 3D printers for high-temperature polymers, and their spare parts

Check all the products below and request a quotation or directly place an order.

Highlighted Products

Apium P220

Apium P220 is an entry-level industrial 3D-Printer designed to process high-temperature polymers including reinforced polymers with up to 30% of fiber content. Apium P220 is based on Material Extrusion Technology (MEX) integrated with Patented technology to process high-performance polymers.

| Product ID: | 4121 |

| Size: | 85cm x 68,5cm x 67,5cm (LxWxH) |

| Weight: | 65 kg |

Product Description

Apium P220

Apium P220 enables the highest part quality in the additive production of high-performance polymers. The P220 is the only printer capable of printing both pure PEEK with high crystallinity and carbon fiber-reinforced PEEK with up to 30% fiber content.

Best part tolerances

The patented Adaptive Heating System analyses the printing geometry and adjusts the heating power to achieve always an optimum energy input. Without thermal post-treatment, you get even finer details and compliance with narrow tolerances. Due to the high stiffness and strength, even embossing dies for aluminum and stainless steel sheets can be printed.

New extrusion technology

Our extruder was developed with flexibility and robustness in mind. The feed force, which is four times higher than that of its previous models, makes it possible to process fiber-reinforced high-performance polymers with a high percentage of filling. The specially designed filament guide automates the loading process.

Monitored printing process

By integrating a camera system, temperature recording, and the use of servo motors, the printing process is continuously monitored. This allows the printer to intervene independently when deviations occur.

Reproducibility

Integrated calibration routines guarantee consistent part quality. The Apium print control software automatically notifies you about maintenance operations and guides you through the procedures step-by-step.

Documentation & Safety

All the important parameters of a printing process are automatically made available in a PDF protocol. The integrated user management prevents any unauthorized access. For your data security, we have decided against cloud-based solutions.

Integrated Software

The control software is specially adapted to our printer hardware and optimized for processing high-performance polymers. An intuitive user interface allows easy operation of the printer. You can manage print jobs and check the status of the printer at any time.

Innovative Materials

The open system allows the use of other materials that are not available in our product portfolio. The P220 also allows the processing of metal-filled filaments which can be sintered.

Technical Support

Our service department will train you in the handling of your printer. We will be happy to answer any questions you may have about the printer and other challenges of 3D printing high-performance polymers.

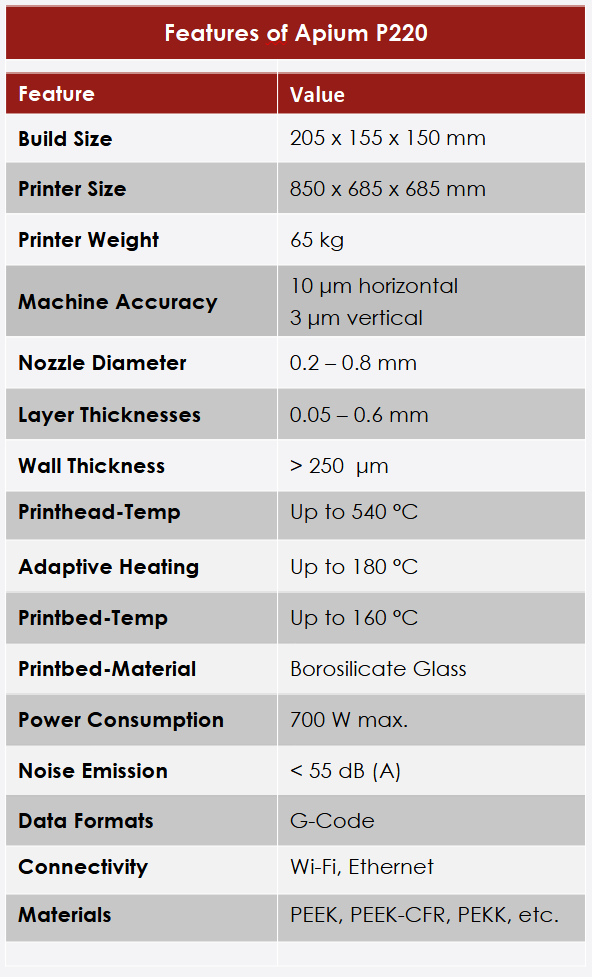

Features of Apium P220:

Important remarks:

- The data have been generated for Apium Additive Technologies in accordance with applicable national, international, and internal standards and are intended for material comparison.

- The typical values may vary depending on part geometry and processing parameters.

For further information and detailed data please contact us.

The materials, products, and services of Apium Additive Technologies GmbH are sold under consideration of the general terms and conditions, which are available on request. By providing the information contained in the data sheets, Apium Additive Technologies is acting in good faith. It is the responsibility of the customer to test and analyze the products for specific applications, suitability, performance, and safety in the end use. Furthermore, Apium Additive Technologies reserves the right to change the products’ specifications and packaging.

If this is not the right material for your application, Check out other materials here.