Introduction

Looking back at 2021, it was an exciting and challenging year for all of us. The importance of additive manufacturing has increased a lot due to worldwide unprecedented events. The CoViD-19 pandemic has still its grasp around the world. The global supply chains vulnerability has been revealed by the ever given container ship incident. All such events demanded the ability to bridge supply gaps and one way was using additive manufacturing to overcome those challenges.

Apium Additive Technologies is proud to be part of the AM community, who helped customers in different industries in overcoming those obstacles. The mutual success of our efforts is reflected in the positive outcome of this year. Thanks to our flexible supply chain we were able to provide our customers with products, services and consumables throughout the year.

Despite the challenges of 2021 the demand of Apium products resulted in an increase of revenue by more than 20% compared to 2020. Keeping the consistent growth of the previous years, reflects on the quality of Apium products and services. Our customer feedback surveys showed that 97% of our customers experienced a very high overall satisfaction.

Reaching to the local manufacturers

As stated in the introduction we had to deal with restricted physical travel. That showed us the importance of a well-functioning reseller network to support the local manufacturers and end users.

Apium Additive Technologies had a significant increase in Value Added Resellers around the world reaching up to more than 50 countries. The unique technology and the advantages of Apiums 3D-printers is getting more and more globally recognized. Together with our resellers we were able identify the customers benefit by using Apiums technology. Thereby we could improve the business activities of local manufacturers and end users in industrial and medical sectors. These improvements result in multiple forms, like in a high degree of design freedom, as a local manufacturer commented „Since we constantly adapt our product design to each application, we cannot go back to traditional manufacturing as it will incur heavy investment eventually making less or no profits.“

Other ways that show the benefits of Apiums technology is reflected in the real life application examples.

Applications - Real life applications

Apium as the first filament based 3D printer manufacturer of high temperature semi crystalline polymers, observed reluctance or unawareness in the market to integrate the technology, as it was mainly used for research purposes. But as stated in the introduction, we have seen the trend that businesses were implementing AM Technologies with a rapid increase during the pandemic. This paved the way for multiple advances in using the technology for real life applications in 2021. Few such examples of applications are:

| Sector | Applications |

| Medical Sector | Printing PEEK Implants for Class III applications |

| Aerospace | Seals, Cases for Cube Sat etc. |

| Oil and Gas Industry | Machinery parts and seals. |

| Automotive | Battery Cases in EVs, etc. |

| Vertical Farming | Mainly PEEK for is chemical resistant properties |

Contribution to prevent the climate change

Another global concern is the fast change of climate caused by fossil energy consumption. Since it is everyone’s responsibility to reduce the carbon foot print where ever it is possible, we are offering a highly sustainable and eco-friendly technology. All the products, such as 3D-printers and dryers, at Apium Additive Technologies consume the lowest energy of all the high temperature polymer processing systems available around the world.

Historical Acheivments in 2021

Medical

This year some ground breaking work has been done by our customers.

Skane University Hospital, in Sweden, performed the Worlds first surgery with 3D printed patient specific impant made completely in a hospital. This is the first hospital to prove the patient related and economic advantages of having full control of whole patient treatment workflow, which is in compliance to the regulatory standards.

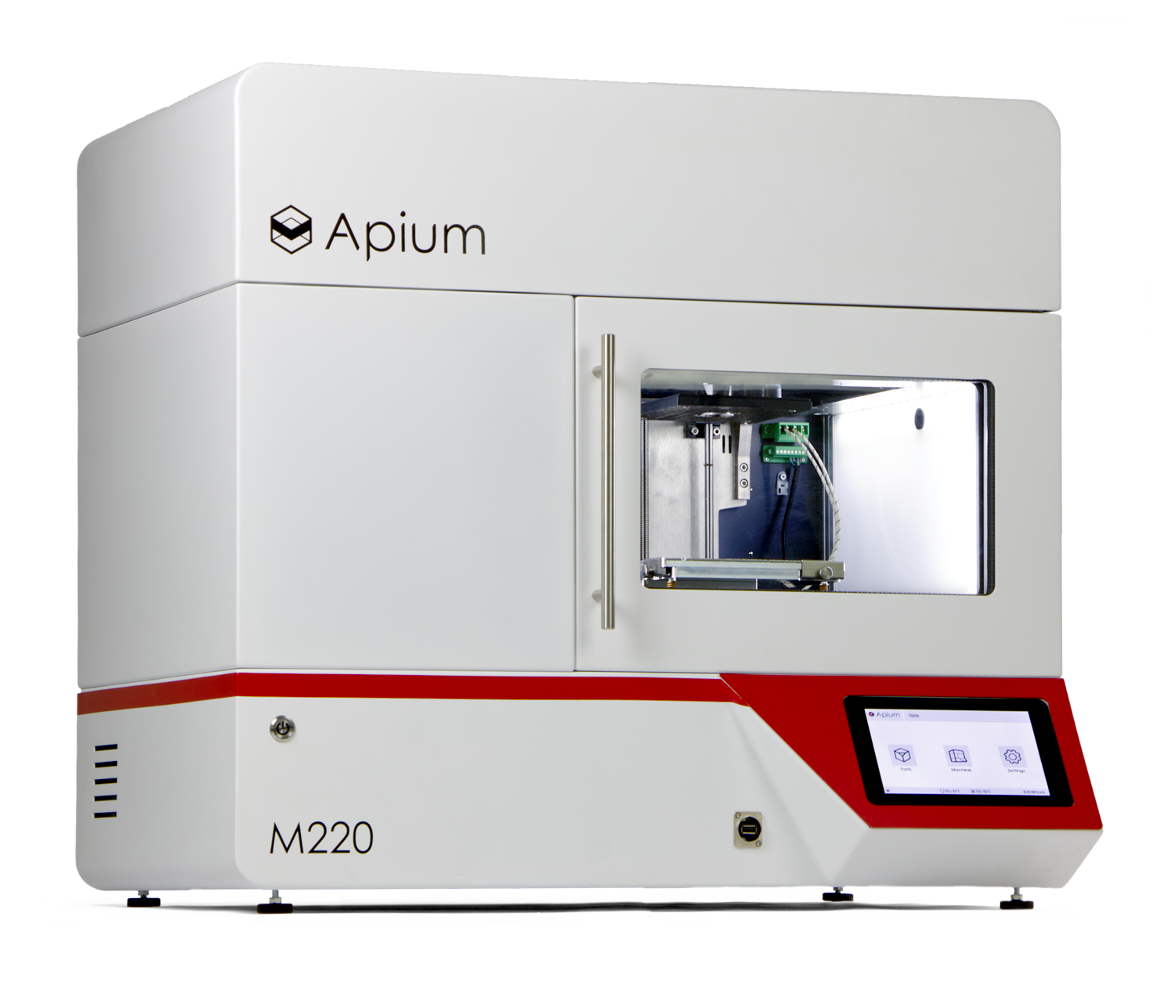

In addition to that hospital based breakthrough, several other groups around the world had successfully performed surgeries by using a 3D-printed Implant manufactured on an Apium M220 3D-printer. In India, the Implant manufacturer Lucid Implants could successfully supply more than 20 PEEK implants within this year. For further details get in touch with us at info@apiumtec.com

Industrial

AHMT, an industrial company based in Germany, was able to set up a small series production of technical parts with real life applications. They have purchased multiple machines and planning to increase their production capacities, solely based on additive manufacturing.

Conclusion

In despite of all the challenges we had to face in 2021, we were still able to maintain our supply chain. Therefore we were able to provide our customers with goods and services without compromising its quality. But the high level of customer care would not have been possible without the efforts of our value added resellers around the globe. As a result of these efforts, we are very proud to see our customers achieving unprecedented accomplishments.

We at Apium take immense pleasure and pride of being part of reshaping medical and industrial manufacturing approaches into new and prosperous grounds. All of this is only possible with good relationships and reliable technology.

Lastly, we thank all the partners and customers for accompanying us on this journey. We are looking forward to all our existing and forthcoming projects with you in 2022.