A cancerous tumor was being developed in a 22 year old boy. The doctors feared that it might reach the vital organs if the tumor is not removed. The solution was a 9 hours long surgery in which the tumor was removed and the resected part was replaced by a single 3D printed PEEK part manufactured on an Apium M220 3D-printer.

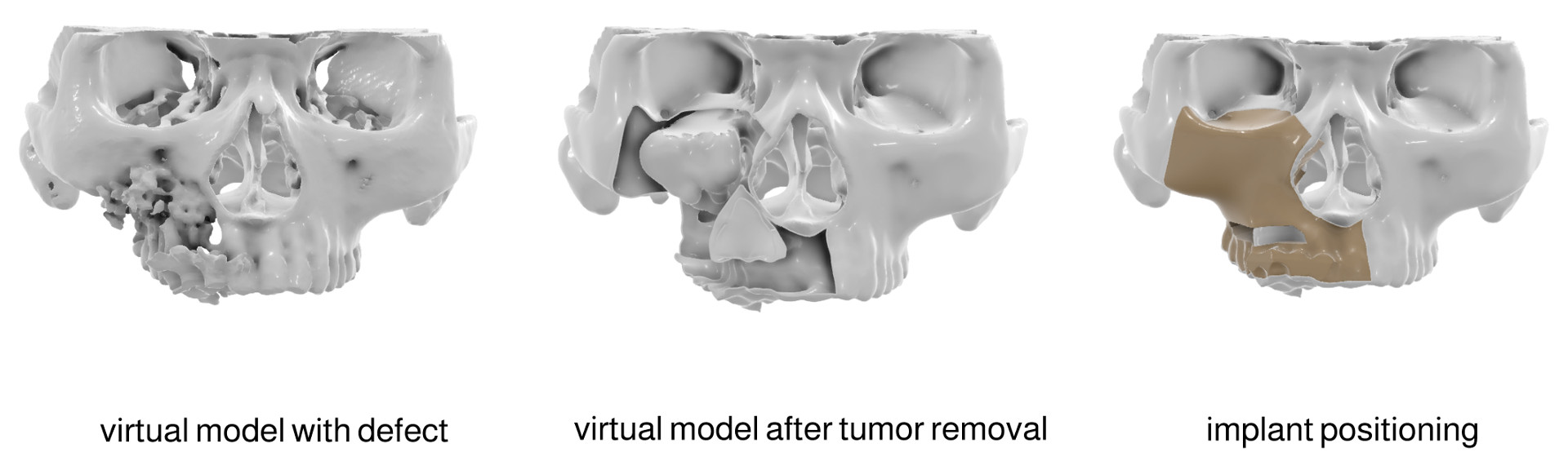

Traditionally to replace such a part, a piece from the patients leg needs to be cut out, reshaped and replaces the facial bone. Thanks to the technological advances, the patient is spared from an additional surgery since the defective part can be replaced by a 3D-printed one. The resected part involved palate, cheekbone, eye socket and upper jaw teeth. The patient was very happy that he had tumor removed and was able to regain the aesthetics of the face.

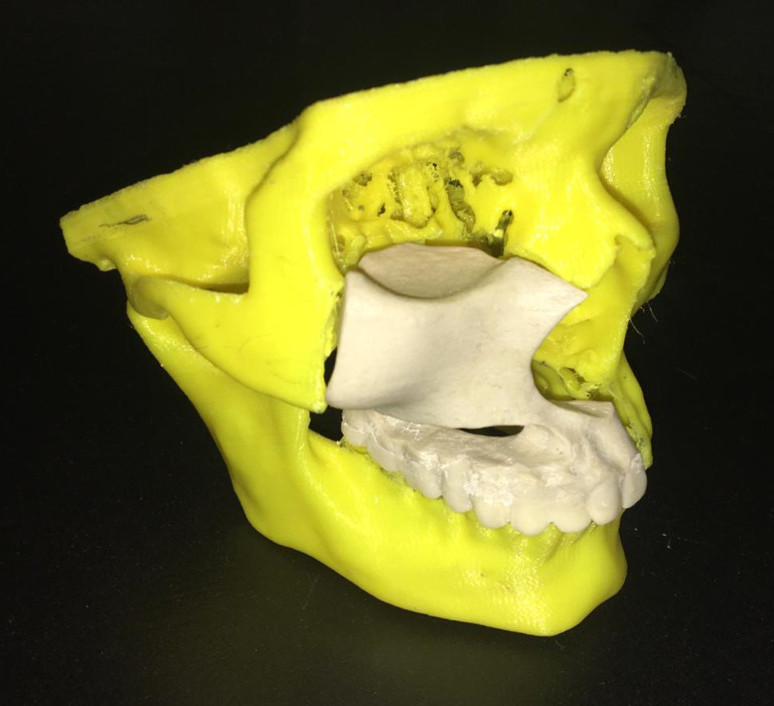

Illustration of the implant position

Photo: Lucid Implants, All Rights Reserved.

CAD illustraiton of replacing the defect (tumor) with 3D printed PEEK implant, Photo: Lucid Implants, All Rights Reserved.