3 Additive Manufacturing applications to benefit from high performance polymers

The introduction of both neat and reinforced high performance thermoplastics to the additive manufacturing (AM) materials portfolio has made it possible for industries having higher product quality and performance requirements to implement 3D printing in their workflow. Apium PEEK 450, CFR PEEK and PEI 9085 (ULTEM) are leading materials for industrial 3D printing. Using additive manufacturing within a value chain, either as a separate or as a hybrid production tool, can markedly increase productivity or accelerate a company’s growth.

In recent times there has been a lot of interest in AM from industrial companies for reasons based on cost and time-to-market. Some of the industrial companies share similar challenges posed by conventional manufacturing methods. Such challenges border on:

- High costs and long delivery lead times for parts with complex geometries and inner channels

- Difficulties in design iteration testing for functional integration of components

- High costs for small quantities or customized production

The goal of this write-up is to highlight some specific part applications and ways by which Materials Extrusion (FFF) 3D printing technology in combination with high performance materials can be advantageously used to optimize fabrication output.

Rapid prototyping

In dynamic and intelligent process chains of R&D infrastructures conventional manufacturing methods are too static to react on multiple experimental design iterations. In the area of motorsports where the general rule is to have an agile product development strategy, AM technologies such as FFF offers the needed flexibility. Through the ability to fabricate variations of parts and geometries using a single tool user can achieve enormous cost and time savings.

Lightweight production

Considering the fact that PEEK can potentially replace metals in lightweight applications over a range of temperatures (typically -196°C to 260°C) makes Apium PEEK and 3D Print technology interesting for lightweight production. Usage of computer-aided designs, which focus on organic geometries and voided architectures within parts results in less internal stresses as well as reduction in overall mass. The image shown in Fig 1 is a topology optimized bracket manufactured with Apium CFR PEEK, where Apium experts could achieve an overall weight-reduction of 43%.

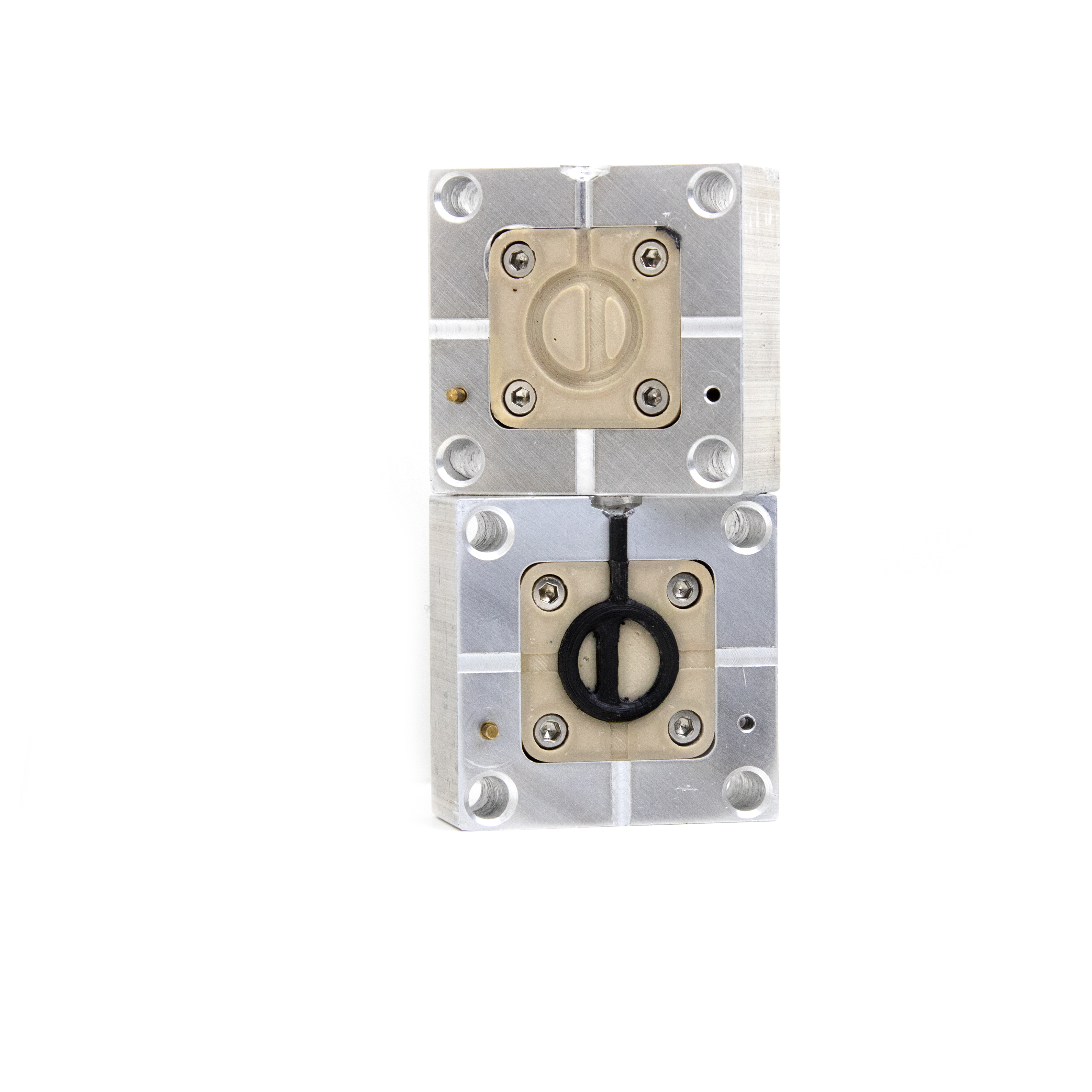

- Implementing inner structures within mould tools without complex machining results in more effective cooling phases which significantly reduces iterations

- Low cost moulds due to reduction in material loss and same-day lead times

Technology from Apium for your success

High performance polymeric materials generally show properties which make them uniquely suitable for a diverse range of industrial applications. With this class of materials solutions for specific requirements, needs and functions in industry can be realized. Apium offers a well-matched material portfolio that optimally meets a variety of requirements. End-users can conveniently test the possibilities offered by Material Extrusion (FFF) 3D printing of high-performance polymers and secure a sustainable business advantage.

Learn more specific facts about the applications mentioned in our eGuide: 3 additive manufacturing applications to benefit from high performance polymers

ULTEM is a trademark of SABIC GLOBAL TECHNOLOGIES B.V.

Discover the possibilities of additive production with high-performance polymers to secure advantages for your company.