Leveraging 3D Printing technologies with a strong industrial partner

In recent times, there have been concerted efforts at advancing the technical and economic promises of 3D printing technologies deep into the manufacturing industry. The development of 3D printing technologies in order to meet manufacturing requirements is still an ongoing process even after over 30 years of introduction as an alternative manufacturing tool. Although significant technological progress has been made to bring the powder-based systems as close as possible to mainstream industrial applications, there still remains some work to be done to manage the entry of the filament based or liquid based (photo-polymer) systems. Whilst these systems have been proven capable for the processing of polymers into functional engineering parts, the influential role of big industry to promote their manufacturing relevance is still lacking.

Materials remain the most decisive aspect of additive manufacturing (AM) or 3D printing technologies. Apium Additive Technologies, an innovations-oriented company based in Karlsruhe, has distinguished itself as a key global solutions provider of 3D printers capable of processing high temperature polymers such as polyethertherketone (PEEK). PEEK is a polymeric material with such cherished attributes that it is especially sought for use in high end applications in the fields of medicine, aerospace, vacuum systems, electronics & semiconductor as well as systems where light weight, high specific strength and corrosion resistance are required. The technology which Apium has developed is based on the fused filament fabrication (FFF) technology. Apium’s technology is unique as it considers the materials science based governing principles which make it possible to process PEEK to qualities fit for industrial applications.

Apium’s FFF 3D Printing technology offers high processing efficiency, easy operating conditions, low cost maintenance and the access to fabricate functional parts from high temperature polymers.

Competence centre Apium Additive Technologies GmbH

In 2014, Indmatec GmbH the forerunner to Apium Additive Technologies GmbH was founded to provide 3D printing based technology which offers industry an access to high temperature polymeric materials. To reach new markets and to make a welcome entry to the international 3D printing space, Apium was founded in 2016. Apium’s technological success rests on its team of engineers, scientists, sales and marketing personnel and the highly talented interns who work tirelessly to ensure that innovative solutions to pressing challenges in the unique processing field of high temperature polymers are brought to end-users. The first commercial FFF 3D printer capable of printing PEEK was launched in 2015 creating a strong global interest in Apium’s technology. Due to the pioneering work Apium as done on 3D printing of PEEK its operating facility located in Karlsruhe now serves as a competence centre for generating knowledge regarding FFF 3D printing of high temperature polymeric materials such as PVDF, POM-C, Ultem (PEI) as well as PEEK filled with carbon fiber. The leadership Apium brings to the additive manufacturing industry is without doubt at least in the fld of high performance polymeric materials. Its clientele is broadening beyond key engineering sectors now to medical, industrial R&D groups as well as university groups intent on taking advantage of the manufacturing freedom offered by 3D printing technologies to process PEEK to geometries hardly possible to create using traditional manufacturing methods.

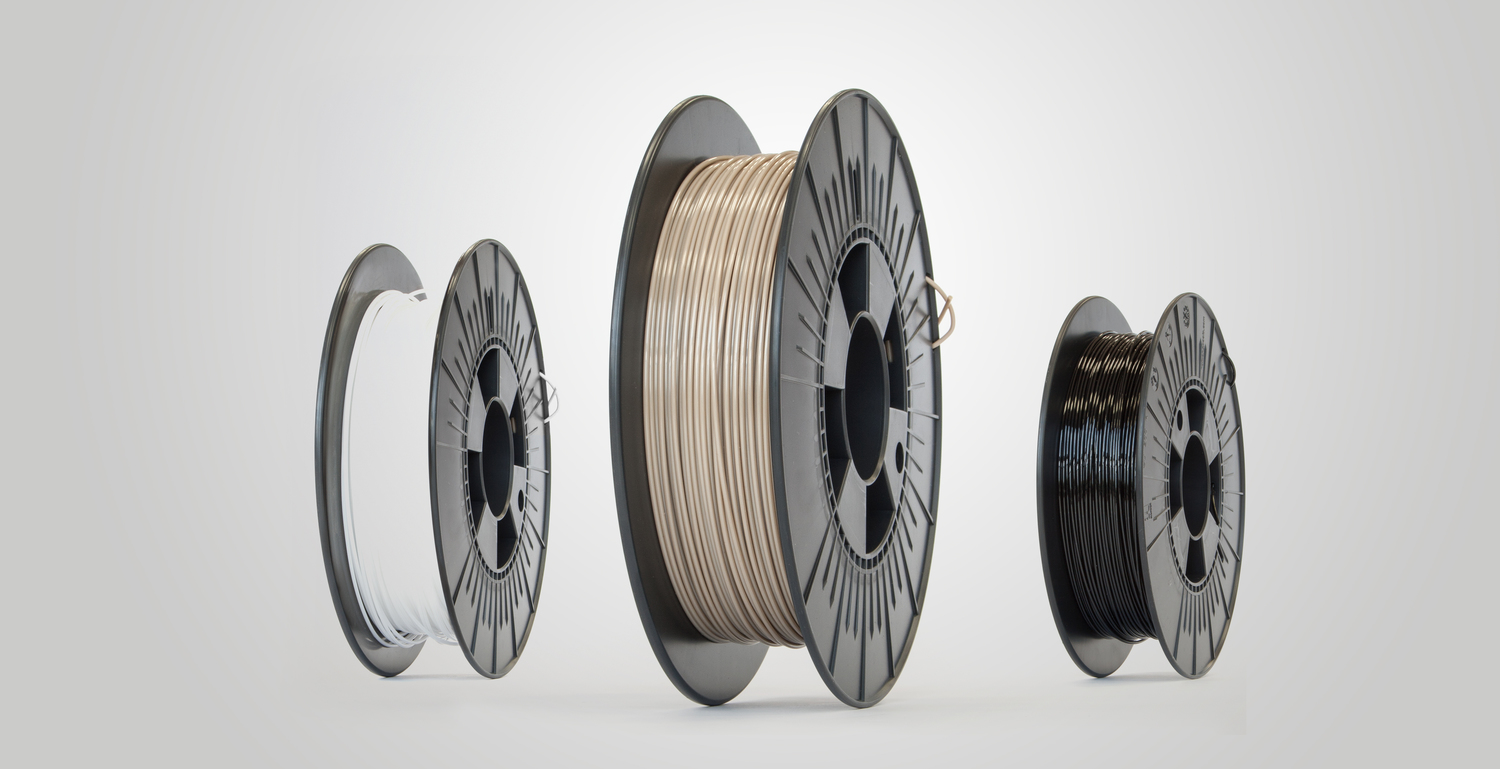

Materials at Apium

Apium’s flagship product, Apium PEEK 450, offers unique mechanical, chemical and thermal properties. PEEK has many advantages over other polymers and is able to replace industrial materials such as aluminium and steel. It’s use in structural applications makes possible reductions in the total weight of systems where mass is a critical efficiency factor especially with respect to energy and agility. Compared to metals, PEEK polymer allows a greater freedom of design and improved performance. Its wide range of operating temperatures (-196°C to 260°C) plays a significant role in applications involving high mechanical and dimensional stability. For the reasons alluded above, PEEK greatly sought in the oil & gas, aerospace, automotive, semiconductors as well as electronics sectors. In the medical sector, due to its biocompatibility, sterilizable nature and tolerance towards radiation in radiology applications PEEK is a choice material for implant and surgical tools.

Apium’s fluoropolymer; Polyvinylidene fluoride (PVDF), is a medium viscosity homopolymer. It exhibits good stability under thermal, chemical or ultraviolet conditions. PVDF is structurally stable up to 149 °C operating temperatures, resistant to most chemicals (solvents) and is generally unaffected by long-term exposure to ultraviolet radiation. Together with these reasons as well as its high resistance to friction especially in wet environments, PVDF is the material solution for challenging deep water applications in the oil & gas industry.

Apium’s Polyoxymethylene co-polymer (POM-C) is a high strength and modulus material lending this material its particularly high resistant to impact and fatigue. Due to its relatively light weight (density is about 6 times and 3 times less than for steel and aluminium respectively), it is often used as a replacement for metals.

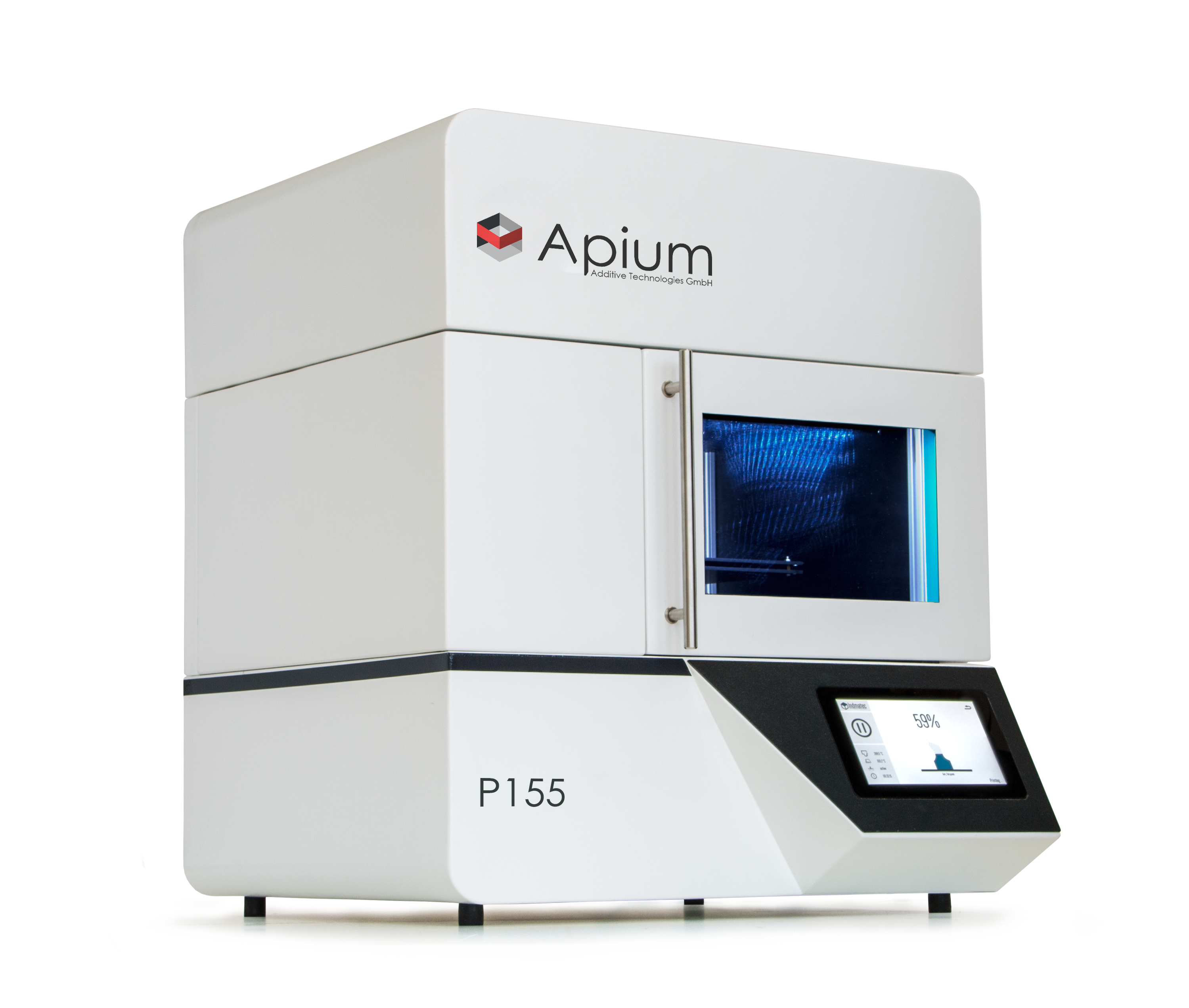

3D printers

Apium’s 3D printing technology guarantees the processing of high temperature polymeric materials. The printer technology currently in its 3rd generation is embodied in the P series 3D printers. These printers have been designed to give a certain technical appeal Apium’s key market segments namely R&D groups at Universities and companies, low volume manufacturing groups and real operating conditions prototyping groups. The operating attributes of the P-series machines make it possible to reach HotEnd temperatures of 520 °C, bed temperatures of up to 160 °C and to alternate across different materials by the mere change of print head in an easy fashion. These attributes ensure that the: (i) part is firmly adhered onto the print-bed, (ii) surface quality of printed parts meet key engineering applications, (iii) mechanical properties of the printed parts compare with materials based bench-marks and (iv) printing process is cost efficient. Apium’s controlling software provides an operator advantaged access to the entire printing process where permutation of printing parameters is possible for the determination of process – property relationships for different printed materials. Additionally, the system performance of Apium’s 3D printers leverages on the materials science which governs polymer processing. This involves an understanding of melt behaviour, phase transformation and the thermo-mechanical influences inherent to the printing system. Apium’s 3D printers deliver the state-of-the-art in FFF 3D printing of high temperature polymers.

Trainings

The practice based knowledge as well as competence being created at Apium is organized in the form of training packages. These trainings typically planned for engineers, technicians and management level personnel allow for the transfer of Apium’s additive manufacturing technology to practitioners in industry. By this Apium is able to inform its clients about best practice in the field of AM and to better understand the applications relevance of Apium’s technology.

Powerful production partners are key to success

Apium’s production partnership with a global first-rate company like Heidelberger Druckmaschinen AG (Heidelberg) makes possible the creation of its industry level P220 series of 3D printers.

Taking advantage of Heidelberger Druckmaschinen AG’s Smart Factory platform which is supported by its highly qualified interdisciplinary teams, Apium is assured that its P220 series 3D printers will meet safety, control, performance and productivity standards of distinction.

On the materials side, Apium’s partnership with Ensinger GmbH gives a firm guarantee that its filaments are of the highest technical quality meeting both physical and chemical specifications needed for the FFF technology. Ensinger GmbH brings along several years of experience in the field of polymer compounding and extrusion. This way, the materials development work at Apium for new FFF 3D printing solutions can be commercialized and provided to industry at economically attractive conditions.

Discover the possibilities of additive production with high-performance polymers to secure advantages for your company.