Metal 3D Printing: An emerging opportunity

If you follow the “money” in the world of 3D Printing, it becomes clear that we are experiencing an era in which investors are betting more on metal based systems than on any other material class. However, it goes without saying that in the global materials market, polymers (thermoplastics and photopolymers) still account for more than two-thirds of the material sales in the field of 3D printing; a market estimated to reach $3 billion by 2018. The pertinent question is, “what is driving the recent surge for metals?”. It might be that metals are indeed the class of material which drives investment in engineering systems such as those found in the aircraft, oil & gas, aerospace and automotive sectors. It might also be that the interest stems from the fact that metallic parts are almost inherently deployable as functional parts rather than as samples for prototyping. Whatever the driving force might be in favour of metal, fact is that 3D printing of metals is a very expensive process. The metallic powders needed for 3D processing are expensive, the material handling raises obnoxious health-safety-environmental issues, laser processing is a high energy demanding process and the process waste material can account for up to 80% of the feedstock.

A possible substitute for powder based technologies is the fused filament fabrication (FFF). One of the key advantages of the FFF 3D printing technology is the ability to consume only the amount of material needed for the part being fabricated/built-up. Also, the materials (typically thermoplastic polymers) used for FFF 3D printing are generally less expensive than those used for any of the other types of 3D printing technologies. Thermoplastics can be composited with a range of other materials by simply filling them in a compounding process. Metals, ceramics, wood, carbon, glass as well as other non-meltable polymers have been used to form polymer matrix composites materials.

Metal polymer matrix material systems can now be processed by injection moulding methods requiring that the granular feedstock is first moulded into parts (so-called green body) then further processed in other to realize the full bulk strength of the metallic phase. The post processing typically involves a de-binding process (catalytic or purely thermal in order to separate the polymer binder phase from the metallic phase) and then a thermal sintering process in which the resultant brown-body is thermally densified to a pore-free solid part.

This processing approach, technically called “metal injection moulding” (MIM), is an established manufacturing process. It combines the benefits of mass production and rapid manufacturing typical of injection moulding with the inherent process safety when compared to metal casting or forging.

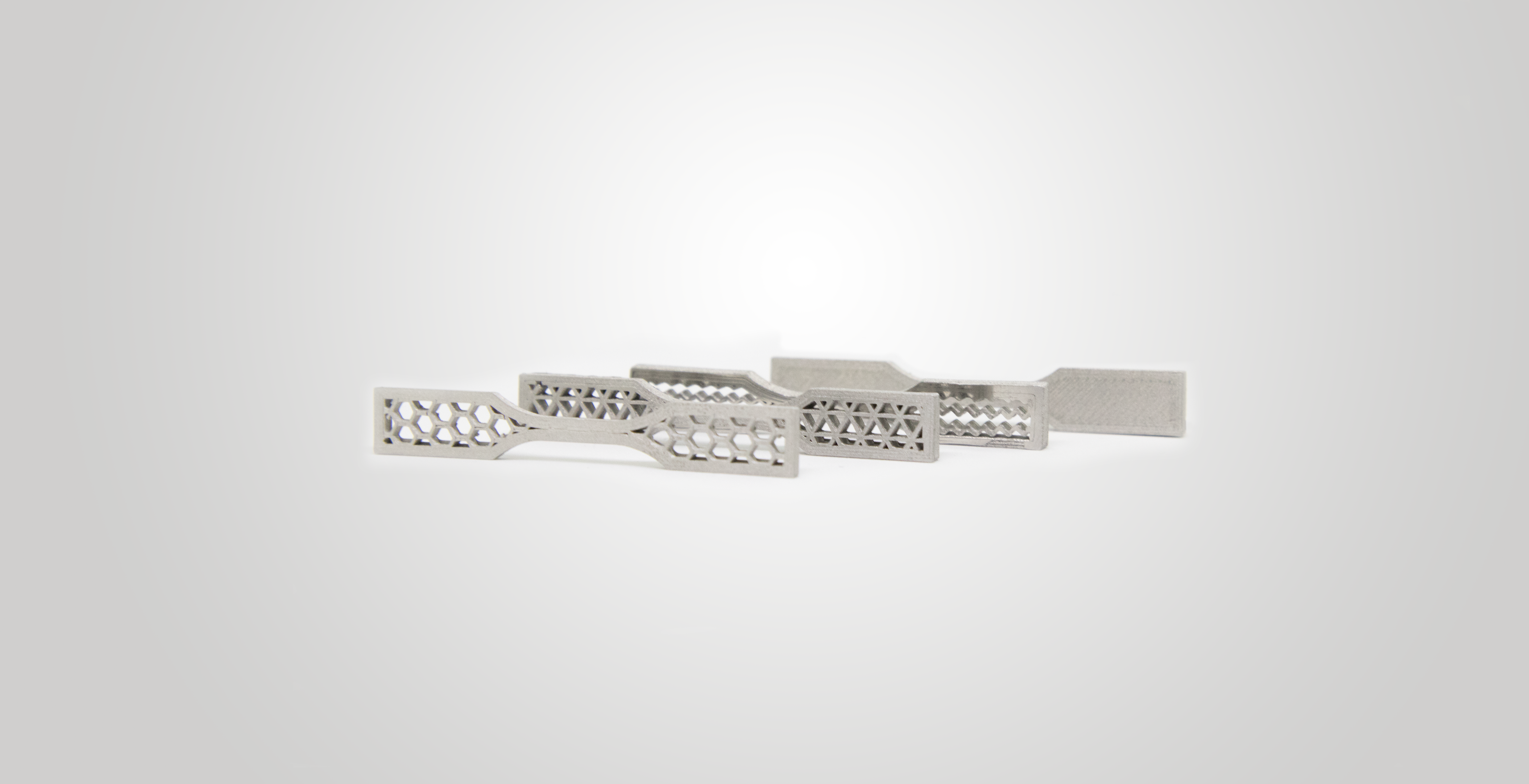

To take these processing advantages further, by using FFF 3D technology so as to manufacture parts which have relatively complex geometries at lower cost, Apium Additive Technologies GmbH has been testing the newly developed Ultrafuse 316LX filament material by BASF. This material consists of a polymeric binder phase with about 80 wt.-% stainless steel 316L particles. The FFF 3D printed green bodies were post processed using first a catalytic acid phase de-binding process followed by sintering in oven.

Here are some of the things we have learnt from processing this 316LX material:

- It can easily be processed using Apium’s FFF 3D printing technology

- The green-body printed from Apium’s printer have structural properties which enhance their survival chances when put through de-binding and sintering processes

- The sintered parts meet geometric requirements

- The mechanical properties of the sintered parts compare quite well with that of bulk 316L stainless steel

- The porosity of the sintered parts is generally below 2%

The ability to fabricate metallic parts using Apium’s FFF 3D printing technology has far reaching effects in the economics of manufacturing. It offers small and medium scale enterprise the chance to prototype or manufacture functional parts in small series at highly competitive costs. Apium is working on a system which integrates the de-binding and sintering within its FFF 3D printing solution.

Contact:

Prof. Dr. Brando Okolo brando.okolo@apiumtec.com

Philipp Renner philipp.renner@apiumtec.com

Discover the possibilities of additive production with high-performance polymers to secure advantages for your company.